Что делает U-образные стальные каналы необходимыми для конструктивной целостности?

Подшипные способности в условиях высокого напряжения

U-образные стальные каналы (U-каналы), включая Каналы UnistrutКлючевые факторы в строительстве сильных структур. Они обрабатывают большие грузы, не будучи тяжелыми. Их форма распределяет стресс равномерно. Это работает как для сил вверх и вниз, так и для сил бок к боку. Это делает их идеальными для тяжелых работ.

Они поддерживают тяжелые весы, не слишком сильно сгибаясь. Вы’ Вы найдете их в местах, нуждающихся в твердой поддержке. Они не’ t не удается легко. Эта сила сохраняет здания безопасными и стабильными в течение многих лет.

Сопротивление к искажению, изгибанию и деформации со временем

Инженеры любят U-образные стальные каналы за их долговечную форму. Древесина или другие материалы могут крутиться или гнить. Сталь остается под давлением. Точное производство - последовательные размеры для беспрепятственной конструкции. Это очень важно в высоких зданиях или заводах. Безопасность и долгая жизнь здесь важны. Стальные каналы не’ t искажение или изменение, даже после лет использования.

Совместимость с бетоном и другими обычными строительными материалами

U-каналы отлично работают с бетоном. Они’ часто устанавливаются в бетонные плиты. Или используется для защиты и укрепления стен. Их прямые края идеально подходят к таким материалам, как кирпичи или сборные панели. Цинковка или порошковое покрытие делает их лучше прилипать к бетону. Эта командная работа создает прочные, долговременные структуры.

Как U-образные стальные каналы работают под стрессом окружающей среды?

Производительность в сейсмических зонах и зонах, подверженных землетрясениям

Землетрясения тяжело испытывают здания. Места, такие как Калифорния или Япония, нуждаются в жестких материалах. У-образные стальные каналы соответствуют задаче. Их равномерная форма хорошо справляется с боковыми силами. Оптимизированная конструкция - фланцы и полоска распределяют напряжение равномерно, повышая конструктивную целостность. Они изгибаются предсказуемо во время землетрясений. Это помогает колоннам и балкам сгибаться без слома. Это делает здания более безопасными, когда земля дрожит.

Коррозионная устойчивость в прибрежных и влажных районах

Сольная вода и влажность могут разрушить материалы. Прибережные районы сталкиваются с этой проблемой. У-образные стальные каналы хорошо борются с ржавью. Коррозионная стойкость - доступна в оцинкованной или окрашенной отделке для повышенной долговечности. Оцинкованные каналы останавливают ржавчину и износ. Они долго сохраняются в влажных местах, таких как Юго-Восточная Азия или рядом с океаном. Это делает их разумным выбором для жестких климатов.

Огнестойкость и термическое расширение

Сталь не’ Легко зажигать. Но она расширяется в тепле. Инженеры планируют это. Они добавляют расширительные соединения или огнеупорные покрытия. Это работает в таких местах, как склады или химические заводы. Сталь’ Поведение в тепле предсказуемо. В отличие от дерева, он выиграл’ Внезапно сгорел. Это помогает обеспечить безопасность сооружений во время пожаров.

Почему стальные каналы в форме U предпочитаются в современных строительных проектах?

Простота установки и конструктивная универсальность

Сегодня’ Строители хотят скорости и качества. У-образные стальные каналы обеспечивают оба. Простая установка - Легкий вес и предназначен для быстрой сборки с помощью винтов или сварки. Они’ re легко перемещать и разрезать на месте. Вы можете использовать винты или сварки, чтобы установить их на своем месте. Они соответствуют традиционным конструкциям или новым сборным системам. Такая гибкость экономит время и усилия.

Эффективность затрат по сравнению с другими вариантами армирования

Создание U-каналов является экономичным. Процессы холодного формирования держат затраты низкими. Они остаются сильными, не разрушая банка. Более низкие затраты – снижение материальных и транспортных расходов. По сравнению с тяжелыми балками или заказными деталями U-каналы дешевле. Они не’ t скупь на силу. Это делает их отличными для таких проектов, как общественное жилье или модернизация дорог.

Роль в модульных и сборных строительных системах

Модульное строительство быстро растет. Это’ в таких местах, как Китай, с их целями зеленого строительства. У-образные стальные каналы идеально подходят для этого. Универсальность - Подходит для крыши, стенной рамы, мезанинных полов и монтажа солнечных панелей. Они надежно соединяют модули. Они также позволяют гибкий дизайн. Это помогает строителям соблюдать новые правила и экономить труд.

Как U-образные стальные каналы используются в реальных приложениях?

Усиление балок, колонн и стенных сборок

В крупных зданиях, таких как торговые центры или больницы, разделение нагрузки является ключевым. У-образные стальные каналы выступают в качестве дополнительной поддержки. Они укрепляют главные лучи. Они’ Также перебросаются в бетонные колонны. Это повышает прочность на растяжение. Держит полы и стены стабильными при тяжелом использовании.

Поддержка крышных конструкций в коммерческих зданиях

Крыши нуждаются в сильных краях. У-каналы обеспечивают это. Они борются с подъемом ветра в бурных районах, таких как Флорида. Их конструкция делает крышные трассы более жесткими. Они используют меньше материала, но хорошо передают нагрузки. Это сохраняет крепкость крыши и экономит ресурсы.

Повышение стабильности инфраструктурных проектов, таких как мосты и туннели

Мосты и туннели сталкиваются с жесткими силами. Автомобили добавляют стабильный вес. Трафик вызывает вибрации. У-образные стальные каналы обрабатывают оба. Применения: Инфраструктура – мосты, платформы. В туннелях они укрепляются против давления почвы. Они также немного сгибаются во время земных сменов. Это обеспечивает безопасность сооружений в сейсмических зонах.

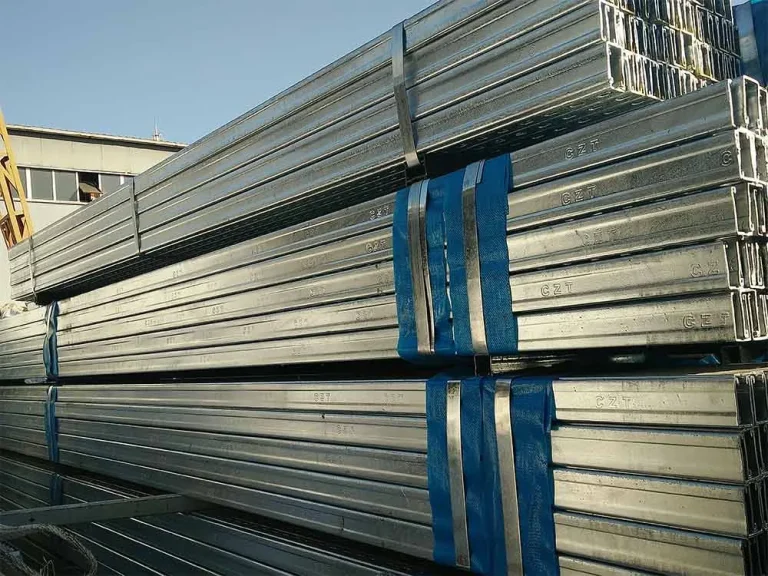

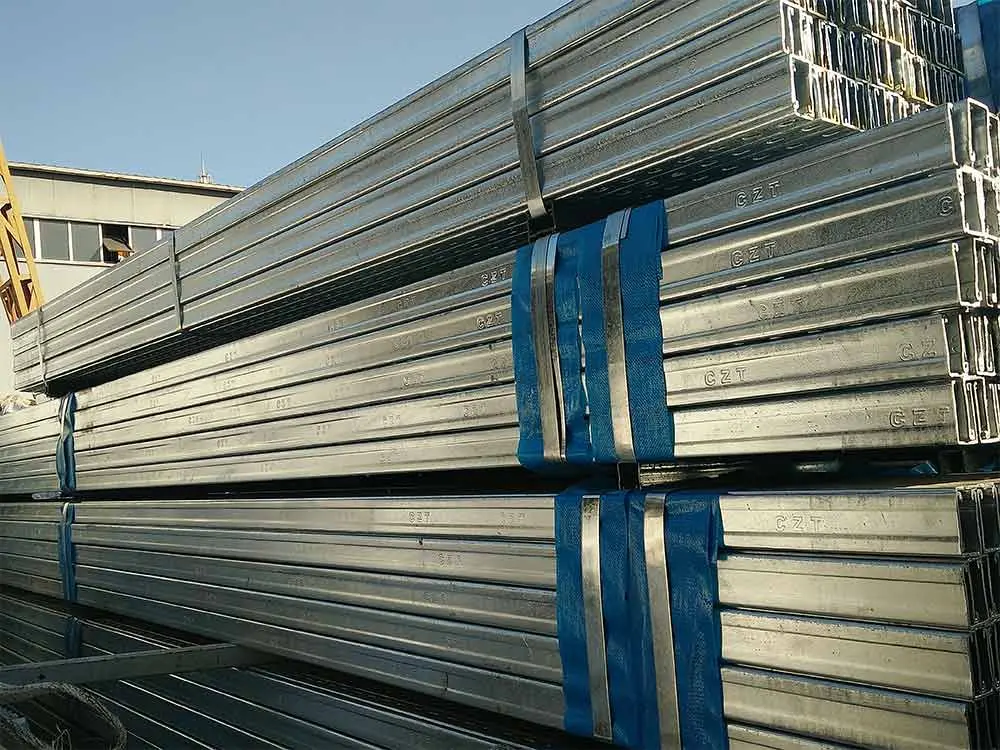

Кто такой CZT и что отличает наши U-образные стальные канальные продукты?

Наша приверженность контролю качества и стандартам материалов

CZT начался в 2013 году в Тяньцзине, Китай’ Большой портовый город. Мы фокусируемся на Сильные строительные решенияЦелью CZT является концепция научного и долгосрочного развития. Мы соблюдаем строгие правила ISO. Каждая партия соответствует жестким глобальным строительным стандартам. Это гарантирует надежность и безопасность нашей продукции.

CZT’ Передовые производственные процессы для точности измерений

Наша фабрика высочайшая. В мастерской холоднообразованной стали есть 25 линий формирования. Мы производим до 5000 тонн в месяц. Толщина поднимается до 10 мм. Мы используем управление 6S для безопасности и скорости. Стальная мастерская холодной формы оснащена 25 холодными линиями … Ежемесячная мощность 5000 тонн. Это делает наши U-каналы точными и последовательными.

Сертификация и соответствие международным строительным кодексам

Мы соблюдаем глобальные правила. Наша продукция имеет сертификаты ISO и SGS. Они работают в Европе, Северной Америке и Азиатско-Тихоокеанском регионе. Сертификация: ISO, SGS. Это означает, что строители доверяют нам во всем мире. Наши каналы подходят для любого проекта’ с потребностями.

Популярные линейки продуктов CZT: холодокатанные U-каналы для долгосрочной долговечности

Наша холодокатанная C-образная/U-образная сталь прочна, но легкая. Это’ с отлично подходит для креплений солнечных панелей, коммерческих крыш или модульных стен. Высокое соотношение прочности к весу - обеспечивает конструктивную поддержку при снижении затрат на материалы. Настройчивая - может быть произведена в различных толщинах. Эти особенности делают их идеальной для долговременной силы.

Почему строители по всей стране выбирают CZT для решений структурной поддержки

CZT обслуживает большие и малые проекты. Мы поддерживаем Китай’ s Пояс & Дорожная инициатива. Мы также помогаем местным строителям жилья. Наша компания имеет международную команду обслуживания, которая может предоставить индивидуальные решения для глобальных клиентов. Наше точное производство и фокус на качестве делают нас лучшим выбором. Строители любят наши надежные, индивидуальные решения.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

В: В чем основное преимущество использования U-образного стального канала над I-балками?

A: I-лучи хорошо обрабатывают вертикальные нагрузки. У-образные стальные каналы добавляют лучшую боковую поддержку. Они’ И легче тоже. Это делает их отличными для работ, требующих боковой силы.

В: Подходят ли стальные каналы в форме U для использования на открытом воздухе?

А: Да, особенно с оцинковкой. Они борются с ржавью в дожде или соленом прибрежном воздухе. Они долго сохраняются в тяжелой погоде.

В: Можно ли использовать стальные каналы в форме U с бетоном?

А: Конечно. Их форма легко вписывается в бетонные плиты или стены. Это повышает прочность во время отлива.

В: Как ведут себя U-образные стальные каналы во время землетрясений?

А: Их равномерная форма изгибается предсказуемо. Это безопасно поглощает энергию землетрясения. Они помогают избежать внезапных перерывов.

В: Возможно ли настроить размеры каналов в форме U?

A: Да, в CZT, мы адаптируем длину, толщину и покрытия к вашему проекту ’ с потребностями.