Perfect Weld Standards and Their Role in Solar Mounting Structures

Perfect weld standards define whether a solar mounting structure can safely perform over its full service life under wind, snow, and thermal stress. In solar projects, a “perfect weld” is not a cosmetic concept but a structural requirement that directly affects load transfer, fatigue resistance, and long-term reliability. For EPC contractors and project owners, weld quality becomes a risk control factor rather than a workshop detail.

Unlike general steel fabrication, solar mounting structures operate outdoors for 25 years or more, often in harsh environments. This reality means weld standards must account for corrosion exposure, cyclic loading, and installation tolerances that do not exist in short-life industrial structures. Understanding how perfect weld standards apply specifically to solar mounting systems is, therefore, essential for technical decision-making and supplier evaluation.

Perfect Weld Standards Used in Solar Mounting Structure Projects

Perfect Weld Standards in International Solar Engineering Codes

Perfect weld standards in solar mounting projects are primarily derived from internationally recognized structural welding codes. These standards provide baseline requirements for weld geometry, penetration, material compatibility, and inspection methods, ensuring that welded joints perform predictably under structural loads.

In utility-scale solar projects, commonly referenced frameworks include structural welding standards aligned with AWS, ISO, and EN systems. These codes define acceptable weld profiles, allowable discontinuities, and qualification requirements for welding procedures and personnel. While the exact code selection may vary by region, the underlying principle is consistent: weld quality must be verifiable, repeatable, and traceable throughout fabrication.

Perfect Weld Acceptance Criteria for Structural Steel Fabrication

Perfect weld acceptance criteria translate abstract standards into measurable fabrication outcomes. In solar mounting structures, acceptance criteria focus on structural performance rather than appearance alone. Weld size consistency, fusion quality, and alignment accuracy are critical to maintaining design load paths.

Compared with general structural steel, solar mounting fabrication places additional emphasis on dimensional stability and tolerance control. Misalignment or inconsistent weld penetration can affect module positioning, tracker movement, or foundation interfaces, making acceptance criteria a practical safeguard for downstream installation and operation.

Perfect Weld Requirements for Different Solar Mounting Structure Types

Perfect Weld Requirements for Fixed Solar Mounting Structures

Perfect weld requirements for fixed solar mounting structures prioritize static load resistance and corrosion durability. These structures must withstand continuous wind pressure and seasonal snow loads without fatigue-related degradation. Weld continuity and uniform throat thickness are particularly important at beam-to-column connections and base interfaces.

In fixed ground-mounted systems, components such as the Carbon steel solar panel structure rely on consistent weld quality to maintain structural rigidity across large arrays. Uniform welds help distribute loads evenly, reducing localized stress concentrations that could shorten service life.

Perfect Weld Requirements for Tracking and Flexible Mounting Systems

Perfect weld requirements get tougher in tracking and flexible mounting systems. This is due to moving parts and repeated loads. Welders often face changing stress. So, fatigue becomes the main worry.

Take the Система отслеживания одной оси as an example. It has moving parts. Weld strength there affects how well it tracks and stays mechanically sound. In bendy systems like the Flexible Solar Mounting Support in Mountains, welds must handle the build-up pull. At the same time, they keep lines straight over long reaches. Here, perfect weld standards stress join depth, flaw limits, and step steadiness. All this cuts risks from fatigue.

Perfect Weld Inspection Methods for Solar Mounting Structures

Perfect Weld Visual Inspection Criteria in Solar Projects

Perfect weld visual inspection criteria provide the first layer of quality verification in solar mounting fabrication. Visual inspection focuses on weld bead shape, uniformity, and surface condition, allowing inspectors to identify obvious defects before advanced testing.

Typical visual checks include:

- Weld bead continuity and symmetry

- Absence of cracks, undercut, and excessive spatter

- Consistent weld size relative to design drawings

Visual inspection is especially important for high-volume components, where early detection of deviations prevents repeated defects across large production batches.

Perfect Weld NDT Methods for Structural Reliability

Perfect weld non-destructive testing (NDT) methods are applied when visual inspection alone cannot ensure structural reliability. In solar mounting structures, NDT is commonly used for critical load-bearing joints or projects with elevated safety requirements.

Common NDT methods include:

- Ultrasonic testing for internal discontinuities

- Magnetic particle inspection for surface and near-surface defects

- Penetrant testing for fine crack detection

By combining visual inspection with targeted NDT, solar projects achieve a balanced approach to quality assurance without high cost or delays.

Perfect Weld Failure Risks and Long-Term Impact on Solar Projects

Perfect Weld Defects and Their Impact on Wind and Snow Load Performance

Perfect weld defects can weaken a solar mounting structure’s fight against weather loads. Poor joins or shallow depth cut real cross-section power. This raises the chances of bending under strong wind or snow.

In areas with wild weather, small weld flaws can grow into cracks over the years. This danger shows why perfect weld standards get checked not just in making. They also fit site load needs.

Perfect Weld Quality and Its Influence on Service Life and O&M Costs

Perfect weld quality shapes long-run operation and upkeep costs. Builds with steady, good welds need fewer checks, less fix work, and a lower chance of part swaps in their work time.

From a full-life view, spending on weld quality cuts surprise stops and boosts asset worth. In big solar sites, these gains add up over many mounting spots. So, weld quality becomes a key planning point, not a side note.

Perfect Weld Trends Shaping Solar Mounting Structures in 2026

Perfect Weld Standard Evolution Driven by Utility-Scale Solar Growth

Perfect weld standards are evolving alongside the rapid growth of utility-scale solar installations. Larger arrays, higher mounting heights, and increased tracker adoption are driving stricter expectations for weld consistency and documentation.

In 2026, procurement processes increasingly require traceable welding records, standardized inspection protocols, and alignment with global engineering benchmarks. These trends reflect a shift toward industrialized solar construction, where repeatability and predictability are essential.

Perfect Weld Quality Expectations from Global Solar Buyers

Global buyers expect perfect weld quality to go beyond just meeting rules. They want clear views and real answers. EPC builders and funders check suppliers on how well they show step control, check skills, and long-term strength.

This change puts more weight on makers who blend welding, building, and quality checks into one system. It cuts changes and job risks.

How CZT Solar Ensures Perfect Weld Standards in Solar Mounting Structures

Perfect Weld Control Across CZT Solar Manufacturing Processes

Perfect weld control is a core part of how we design and manufacture solar mounting structures at CZT solar. We select welding methods based on component geometry, load requirements, and material characteristics, ensuring that each joint meets its functional purpose rather than relying on a one-size-fits-all approach.

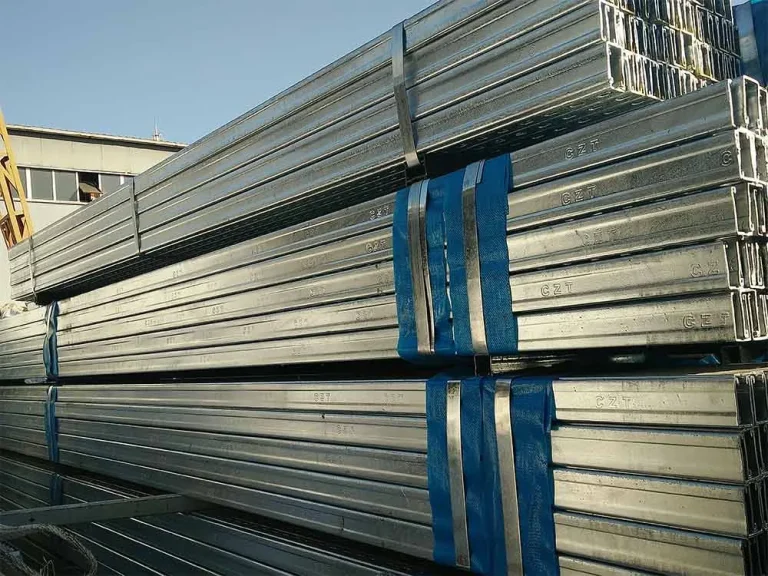

Items like the Zn-Al-Mg Steel Ground Mounting Structure and the H Type Pile Foundation for Solar Ground Mounting System benefit from set welding steps. These steps aid rust fight and build steadiness. We mix cold shaping, welding, and early assembly. This keeps size accuracy and cuts, making changes.

Perfect Weld Quality Assurance Supporting Solar Project Decisions

Perfect weld quality assurance at CZT solar supports informed project decisions by providing consistency and reliability across production batches. Our inspection processes align with international structural expectations, combining visual checks with appropriate testing to match project risk levels.

This approach allows EPC partners to evaluate mounting structures with confidence, knowing that weld quality supports both immediate installation needs and long-term structural performance without unnecessary complexity or cost escalation.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Q: What defines perfect weld standards in solar mounting structures?

A: Perfect weld standards in solar mounting structures define acceptable weld geometry, penetration, defect limits, and inspection requirements to ensure structural safety under long-term environmental loads.

Q: How do perfect weld standards differ between solar mounting structures and general steel fabrication?

A: Perfect weld standards for solar mounting structures place greater emphasis on fatigue resistance, corrosion exposure, and dimensional accuracy due to long service life and outdoor conditions.

Q: How to choose solar mounting structures that meet perfect weld standards?

A: Choosing solar mounting structures that meet perfect weld standards involves evaluating supplier welding processes, inspection methods, material compatibility, and documented quality control systems.

Q: Perfect weld standards vs visual inspection: which is more important?

A: Perfect weld standards define the requirements, while visual inspection verifies surface quality; both are necessary, but standards provide the framework for deeper inspection and testing decisions.

Q: Which brand offers solar mounting structures aligned with perfect weld standards?

A: Brands with integrated manufacturing and quality assurance systems, such as CZT solar, are better positioned to deliver solar mounting structures aligned with perfect weld standards across different project types.