The C shape steel bar stands out in construction for its strength and efficiency. Its unique design offers multiple benefits, making it a top choice for builders. This article explores why the C shape steel bar excels, focusing on its structural perks and practical uses in modern projects.

Why Is a C Shape Steel Bar Structurally Efficient in Construction?

How the Open Section Design Enhances Load Distribution

The C shape steel bar, also called C-Purlin or C-Channel, is efficient due to its open design. This shape spreads loads well in many building tasks. The “C” profile resists bending and shear forces along one direction. This makes it great for jobs needing strength in a specific axis. For example, it works well in wall studs, floor joists, and roof purlins. The open design uses less material than solid shapes. Yet, it still handles vertical loads effectively. By placing material where it matters most—along the flanges—it boosts stiffness while keeping the web slim to save weight.

The Role of Flange and Web Geometry in Structural Strength

The flanges and web of a C shape steel bar are key to its strength. Wide flanges fight against twisting and bending, boosting stiffness. The vertical web handles shear forces well without adding much weight. Engineers can adjust the thickness of these parts to meet specific needs. This avoids overbuilding, which saves material. The result is a lightweight but strong option compared to heavier sections. This balance makes C shape bars a smart choice for many projects.

Comparing C Shape Steel Bars with I-Beams and Square Tubes

C shape steel bars have unique strengths compared to I-beams and square tubes. H Steel Beam, or H-Shaped Steel, supports loads in two directions. However, it’s heavier and uses more material. Square tubes resist twisting well but aren’t ideal for directional loads due to their even shape. In contrast, C shape bars are lightweight and cost-effective. They shine in construction, industrial buildings, and infrastructure where directional strength matters most. Their open profile also fits easily into framing systems, unlike multi-axis-focused options.

What Makes a C Shape Steel Bar Ideal for Lightweight Frameworks?

Balancing Strength-to-Weight Ratio for Optimal Performance

The C shape steel bar offers a great strength-to-weight ratio. Its cold-formed design maximizes efficiency with minimal material. The flanges, placed at the edges, provide strong resistance to bending. This allows high stiffness with less steel than solid or closed shapes. In seismic zones or tall structures, reducing weight is critical. The C shape bar cuts dead loads without losing safety or performance. This makes it perfect for lightweight frameworks.

Reducing Material Usage Without Compromising Integrity

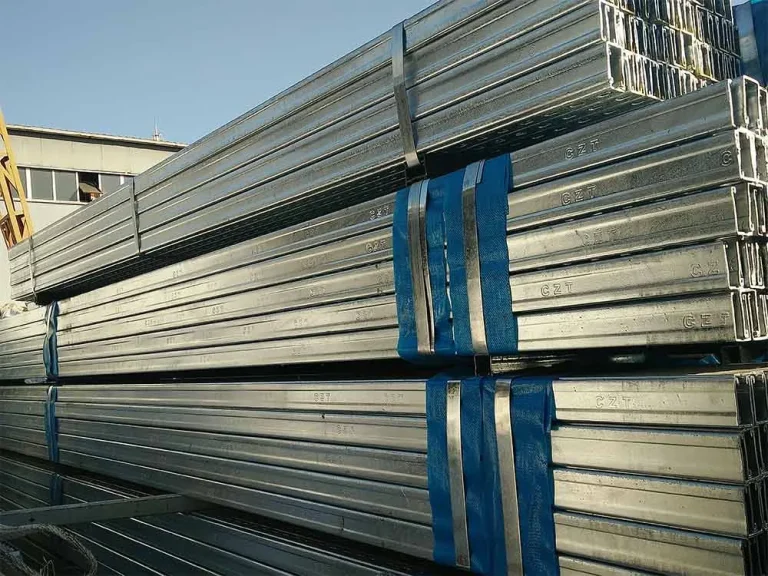

The C shape steel bar uses material only where needed. This lowers costs and supports green building practices by cutting resource use. The open design also makes cutting and joining easier during fabrication. This reduces waste on-site. At CZT, our cold-formed steel workshop has 25 forming lines. These produce various steel products with a monthly capacity of 5,000 tons. This setup ensures precise dimensions and high output, helping builders save resources.

Applications Where Weight Reduction Is Critical

C shape steel bars are common in projects needing light materials. These include pre-engineered buildings, temporary structures, and modular homes. They’re also used in rail shelters and roadside sign frames. Their lightweight simplifies handling during setup. It also reduces stress on foundations. These traits make C shape bars vital for fast, flexible, and eco-friendly construction.

How Does a C Shape Steel Bar Perform Under Stress and Load?

Resistance to Bending, Shear, and Torsional Forces

A well-crafted C shape steel bar handles common stresses well. The vertical web takes on shear forces effectively. Meanwhile, the wide flanges resist bending in their main direction. While open shapes like C-channels are weaker against twisting than closed ones like square tubes, they work well when braced. For instance, they perform strongly in sheathed walls or trussed setups.

Behavior Under Axial and Lateral Loads

Under compression or tension, C shape bars carry significant loads if aligned properly. Their uneven shape means they need careful placement to avoid twisting under pressure. For lateral forces, combining multiple C shape bars into boxed or back-to-back setups boosts stability. This is common in truss or portal frame designs. It keeps members strong without needing larger sizes.

Performance in Long-Span Structures and Cantilevers

In long-span setups like roof purlins or column supports, C shape bars provide solid stiffness with low weight. They span long distances without extra supports, simplifying construction. In cantilevers, their directional strength is useful. However, extra bracing may be needed at fixed ends to handle uneven loads. This ensures reliable performance.

In What Ways Does a C Shape Steel Bar Support Cost-Effective Construction?

Simplified Fabrication and Installation Processes

C shape steel bars are easy to work with. Their even profile makes cutting and punching straightforward. At CZT, our workshop follows the 6S management system. This ensures a smooth and safe production process. As a result, assembly on-site is faster, cutting labor costs. Cold-forming technology also allows precise sizing without much post-processing. This further reduces expenses during manufacturing.

Compatibility with Standard Fasteners and Connectors

C shape bars have standard sizes and flange widths. They work well with common bolts, self-drilling screws, and framing brackets. This avoids the need for custom hardware, which can raise costs. Builders benefit from smooth logistics. They face fewer delays from parts that don’t fit, saving time and money.

Lower Maintenance Requirements Over Time

Steel’s natural durability ensures C shape bars last long, even in tough conditions. When coated or galvanized, as offered by CZT, they resist rust well. This reduces upkeep needs over the years of use. These bars are ideal for industrial or outdoor settings where moisture could harm untreated materials. Their long life makes them a cost-effective choice.

Why Choose CZT’s C Shape Steel Bar for Structural Applications?

Who We Are at CZT: Our Commitment to Quality Steel Products

At CZT, we focus on high-quality cold-formed structural parts for modern building needs. Our cold-formed steel workshop has 25 forming lines. These produce 5,000 tons of steel products monthly. We operate under strict 6S management standards. This ensures every batch is consistent. Our C shape steel bar line serves residential, industrial, and modular projects worldwide.

Specifications of CZT’s C Shape Steel Bars

- Material Grades and Surface Finishes

Our C shape bars use high-strength galvanized steel. They meet standards like ASTM A653/A1003 based on client needs. We offer hot-dip galvanizing for rust protection. Pre-painted finishes are also available on request.

- Dimensional Range and Customization Options

We provide a wide range of sizes. Depths range from 40mm to 300mm. Thicknesses go from 1mm to 10mm. Our advanced forming lines ensure tight tolerances. This allows customization for specific project needs at scale.

- Corrosion Resistance Features

CZT products come with anti-rust coatings. These suits are for coastal or harsh industrial settings. They ensure long life even in tough conditions.

- Compliance with International Standards

Our products meet global codes like ISO9001. We also follow region-specific rules for Europe and Southeast Asia. This shows our commitment to reliable quality worldwide.

Where Our C Shape Steel Bars Excel in Structural Use

Residential Framing Systems

Our C shape bars are light but strong. They work well as roof rafters or wall studs. They suit prefabricated homes, aiming for speed and durability. When paired with insulation and vapor barriers, they meet green building standards like LEED or BREEAM.

Industrial Support Structures

From factory platforms to conveyor supports, our bars adapt to various needs. Their wide size range lets engineers pick the right fit for static or dynamic loads.

Modular Building Assemblies

Modular builders choose CZT’s precise components. They simplify transport and assembly. Our CNC-driven production ensures zero errors, supporting fast workflows.

FAQ

Q: What brand offers reliable C shape steel bar products?

A: CZT is known for high-quality C shape steel bars. We use advanced cold-forming and 6S standards. Our 5,000-ton monthly output ensures supply for large projects.

Q: How do I choose the right type of C shape steel bar?

A: Consider load needs, environmental exposure, space limits, and material compatibility. CZT offers customizable options to match your project.

Q: Is a C shape steel bar better than an I-beam?

A: For directional strength with less weight and cost, like in studs or purlins, C shape bars are better. I-beams suit two-way load support.

Q: What are the top companies producing structural-grade C shaped channels?

A: CZT is a leader with 25 forming lines and global quality standards.

Q: Can I use CZT’s C shaped channels outdoors?

A: Yes, CZT’s galvanized finishes resist rust, making them suitable for coastal or outdoor use.