Which Materials Are Commonly Used in PV Panel Mounting Brackets and Why Do They Matter?

How Aluminum Enhances Durability and Corrosion Resistance in Solar Brackets

Aluminum is one of the most popular choices for mounting brackets on PV panels. It’s lightweight, yet highly durable, and resists rusting very well. Its surface has a natural protective coat that can resist corrosion. It’s therefore perfect to be used outdoors for dozens of years. It suits locations with lots of rain or coastal areas where salty air corrodes other metals.

Aluminum is easy to move and install because it’s so light. That’s useful on rooftops where heavy items are not allowed. Also, it pulls heat away from solar panels. This keeps them working better.

The Strength and Longevity of Stainless Steel for PV Panel Mounting Systems

Stainless steel is really strong for solar mounting systems. It fights rust and handles hot weather well. For big ground setups or places with harsh weather, it stays solid.

It can take heavy wind or snow without bending. It also holds up in acidic or salty conditions. But it’s heavier and costs more than aluminum. So, it’s often used for important parts like bolts or joints, not the whole bracket.

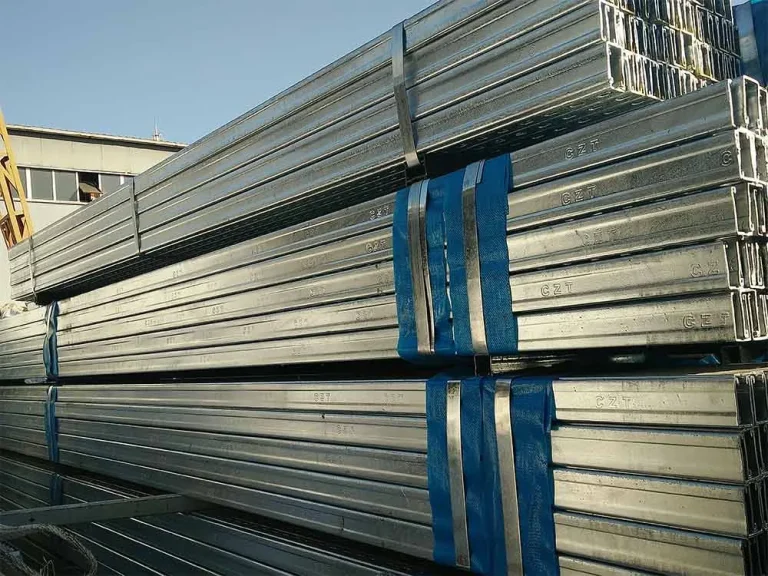

Evaluating Galvanized Steel: Cost-Effective but Heavy

Galvanized steel is steel with a zinc coating. It’s a cheap option for PV panel mounting brackets. The zinc keeps rust away by taking the hit first. It’s strong but much heavier than aluminum or plastics.

Composite and Polymer Brackets: Lightweight Alternatives with Limitations

Composites and strong plastics are new choices for PV panel mounting systems. They stand up to UV rays and rust. They’re also super light and easy to carry during setup. But they’re not as tough for big or windy projects.

They work best for small home rooftop systems. They’re not great for large commercial or utility projects. Plus, we don’t know as much about how long they last compared to metals like aluminum or galvanized steel.

How Do Environmental Conditions Influence the Choice of Solar Panel Mounting Materials?

The Impact of Coastal, Desert, and High-Humidity Climates on Material Performance

The environment matters a lot when picking materials for PV panel mounting brackets. In coastal areas, salty air makes rust happen faster. Stainless steel or coated aluminum is best here because they fight corrosion well.

In deserts with strong sun and sand, you need UV-resistant coatings and tough finishes. In wet tropical areas, materials must stop rust and mold for a long time.

CZT’s flexible solar mounting support is a large-span, high-clearance, multi-span structure. With steady water levels, it allows rigid columns, foundations, and flexible supports in lakes or fish ponds. This shows how CZT uses materials like HDG & Al-Zn-Mg steel for hard natural settings.

Resistance to UV Exposure, Wind Load, and Temperature Fluctuations

PV panel mounting systems need to last for years under sunlight without breaking or fading. Aluminum with anodizing or powder coatings handles UV rays nicely. Stainless steel stays strong under long sun exposure, too, but it’s pricier.

Wind is a big deal. Systems must hold up against storm forces. 216km/h wind load and 1.4kn/㎡ snow load show CZT’s designs are built strongly for different weather conditions.

Temperature changes are important too. Materials and panels need to expand at similar rates. This prevents cracks or loose parts when it gets hot or cold.

Material Suitability for Rooftop vs. Ground-Mounted PV Installations

Rooftop systems need light materials like aluminum. Buildings can’t handle heavy loads. Aluminum is easy to work with, which saves money on labor for sloped roofs.

Ground-mounted systems have fewer weight limits. But they face more wind in open fields. Zn-Al-Mg steel from CZT gives a great mix of strength and rust protection for these projects.

What Are the Structural and Mechanical Requirements for Long-Lasting PV Panel Brackets?

Load-Bearing Capacity and Wind Resistance Standards

A solid PV panel mounting bracket must handle wind and snow loads. 1.4kn/㎡ snow load shows CZT’s products can take heavy snow in northern areas.

Following global codes like ASCE 7 or Eurocode keeps things safe in different places.

Importance of Thermal Expansion Compatibility with Solar Panels

Materials expand differently when heated. If brackets and panels don’t match, this can cause warping or loosening over time.

Aluminum’s expansion rate is close to that of silicon-based solar panels. This makes it awesome for reducing stress at connection points during temperature changes.

Fastening Systems and Joint Stability in Different Material Types

A solar racking system’s strength depends on its fasteners—bolts, rivets, or clamps. These must stay steady under wind shakes or earthquakes.

Stainless steel fasteners are often used with aluminum frames. They’re strong and stop rust at contact points. This is key when mixing metals to avoid galvanic corrosion.

How Do Installation Methods Vary Based on the Type of Mounting Bracket Material?

Pre-Assembled vs. On-Site Assembly Considerations

Pre-assembled kits save time. But they may not fit odd roof shapes or bumpy ground. On-site assembly gives more options but needs workers who know how to handle materials like galvanized steel or tensioned cable structures.

CZT’s structure uses prestressed steel cables stretched between two fixed points. It only needs foundations set in the right spots. This works great for tricky terrains.

Ease of Drilling, Cutting, and Handling by Installers

Aluminum is soft and easy to cut or drill on-site with regular tools. This saves wear on equipment compared to harder metals like stainless steel, which need special tools.

Galvanized steel parts may need re-coating after cutting to stop rust at exposed edges. Factory-made holes can make things faster.

Maintenance Requirements by Material Type Over Time

Aluminum needs little care because of its natural rust protection. You just check it now and then. Galvanized systems need checks for coating damage, especially where water sits.

Stainless steel lasts a long time. But in salty marine areas, check it regularly for surface damage over decades.

Why Is CZT a Trusted Manufacturer of Durable Solar Panel Mounting Brackets?

Our Commitment to Engineering High-Strength Aluminum Alloy Brackets

At CZT, we make tough aluminum alloy brackets for home rooftops and big solar arrays. We use careful cold-forming techniques. These keep the metal strong and precise without losing quality.

CZT’s Anti-Corrosion Coating Technology for Harsh Environments

We use top coatings like hot-dip galvanization (HDG) and Zn-Al-Mg alloy treatments. These fit different needs. HDG & Al-Zn-Mg steel works well in tough spots, like lake or fish pond setups in hilly areas.

Product Range Overview: Adjustable Roof Mounts, Fixed Ground Racks, Tilted Frames

Our products include adjustable tilt roof mounts for better solar angles, fixed ground racks with wide tilt ranges, and flexible frames for different terrains. Our fixed PV brackets, various photovoltaic bracket accessories (ground mounting bracket systems, roof mounting bracket systems).

Certifications and Testing That Validate CZT’s Quality Standards

CZT has 7+ qualification certificates that meet global quality rules. Our 28,000 square meter factory produces up to 10GW annually. Our standard industrial plant area is 28,000 square meters, with an annual production capacity of 10G watts. This ensures customers get strong, tested solutions.

FAQ

Q: What are the best materials used in PV panel mounting brackets?

A: Top choices are aluminum alloys for lightweight and rust resistance, stainless steel for strength, galvanized steel for low cost, and composites for light setups with some strength limits.

Q: How do I choose PV panel mounting brackets based on the environment?

A: Use stainless steel or coated aluminum for salty coastal areas. Pick UV-resistant plastics for low-load home setups. Choose galvanized steel inland where humidity is moderate and budgets are tight. Always check local wind and snow loads.

Q: Are galvanized PV panel mounting brackets reliable?

A: Yes. With proper hot-dip galvanization, like CZT’s, they fight rust well and stay affordable.

Q: Which brand offers durable PV panel mounting brackets?

A: CZT is a trusted name. We offer HDG & Zn-Al-Mg steel products with strong ratings, like the wind load is 216km/h and the snow load is 1.4kn/㎡, backed by a 15-year warranty for rooftop and ground setups.

Q: What factors affect the longevity of PV panel mounting brackets?

A: Key factors are material type (aluminum, galvanized, or stainless), environmental exposure (humidity, salt, wind), thermal expansion match with panels, joint quality, and regular checks like inspections.