What Makes Hot Rolled Steel Shapes Unique in Structure and Performance?

How the High-Temperature Process Impacts Steel Characteristics

Hot rolled steel formations occur when steel is rolled over 1700°F. That is hotter than most steels re-form their grain. The surplus heat gives hot rolled steel its own unique properties. It softens the metal so it will bend into huge shapes like I-beams, bars, and plates.

The heat also changes the steel’s inner structure. Grains become more even, and built-up stresses ease as the steel cools. But cooling can happen unevenly. This may cause slight twists or bends. As a result, hot rolled steel has less exact sizes compared to cold rolled steel. Even so, it’s valued for its strength and use in building projects.

Why Hot Rolled Steel Offers Better Workability and Formability

Hot rolled steel is simpler to shape compared to cold rolled steel. It is due to the hot process that it becomes softer. Cutting, bending, or punching is facilitated. For use where great amounts of material need to be shaped in a rush, hot rolled steel saves time and tool longevity.

It won’t crack or stress tools too much. It is great to use where size precision is not necessary but strength is, like making machine components or frames.

What Surface and Dimensional Traits Are Typical of Hot Rolled Steel?

Hot rolled steel often has a rougher surface because of the scale that forms when it cools. Also, it shrinks unevenly as it cools. This leads to wider size ranges. While this might seem like a drawback for precise parts, it works well for big building tasks where exact measurements aren’t the main focus.

Common shapes include H-beams and wide flange beams. H-Beam Steel, also known as H-Shaped Steel, is a structural steel member with an “H”-shaped cross-section. It’s widely used in construction, bridges, industrial frameworks, and tall buildings. Its high weight-bearing ability, steadiness, and good weight spread make it a top choice.

How Does Cold Rolling Change the Material Properties of Steel?

What Happens to Steel During Cold Rolling at Room Temperature?

Cold rolling happens at room temperature after hot rolling. The cooled steel goes through rollers under strong pressure. This reduces thickness and smooths the surface. The process tightens the metal’s inner grain structure.

This creates strain hardening. It makes the steel stronger but less flexible. Unlike hot rolling, cold rolling doesn’t reshape grains. So, inner stresses stay unless the steel is heated again later.

How Does Cold Rolled Steel Achieve Higher Strength and Precision?

Cold rolled steel has better strength, like higher pull and yield strength, due to the hardening from rolling. Its tighter size control makes it perfect for parts needing exact fits.

Also, cold rolling gives a smooth surface without scale or rust marks. This suits parts that need to look good or take coatings, like paint.

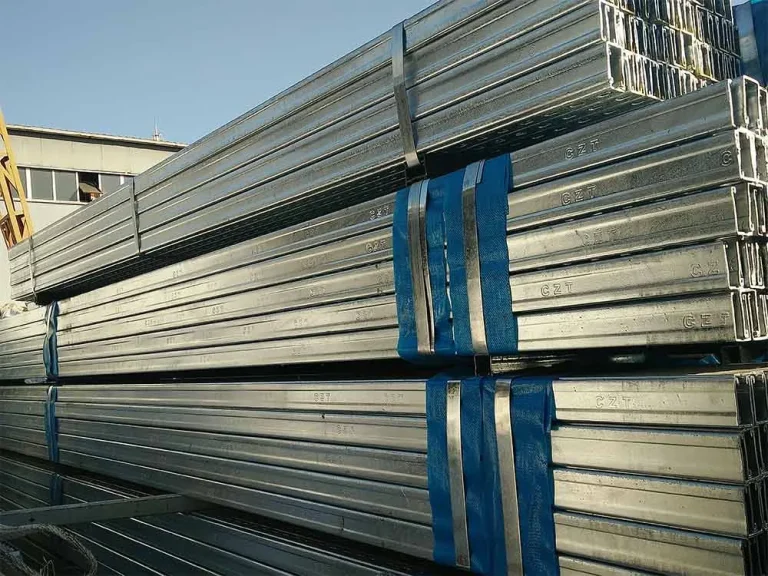

C-shaped steel, also known as C-Purlin or C-Channel, is a cold-formed structural steel section with a distinctive “C” cross-section. It’s used in construction, industrial buildings, and infrastructure. Its light weight, high strength, and low cost make it popular.

Why Surface Finish and Tolerance Are Superior in Cold Rolled Products

Cold rolled steel has no scale and uses precise roller control. This creates a very even surface. It’s ideal for parts where looks matter or tight fits are needed, like brackets or covers.

Cold rolling also controls thickness better over long pieces. This is key for automated factories that need steady material.

Where Do Hot Rolled and Cold Rolled Steel Perform Differently in Real Applications?

Which Industries Prefer Hot Rolled Steel Shapes and Why?

Industries like construction and heavy equipment prefer hot rolled steel shapes. They offer strong, low-cost solutions for big spans or heavy weights. H-Beam Steel is widely used in construction, bridges, and industrial frameworks. It’s ideal for load-bearing columns or support beams where looks or small size changes don’t matter.

For example, bridge supports or building frames often use hot rolled H-beams. They spread weight well.

What Applications Benefit Most from the Precision of Cold Rolled Steel?

Cold rolled steel shines in uses needing exact sizes and smooth finishes, like car parts, home appliances, electrical boxes, or solar panel mounting systems.

C-shaped steel is used in construction, but also fits where light, strong framing is needed without losing alignment. This is key for modular setups like solar arrays.

How Do Material Stress Levels Affect End-Use Performance?

Stress levels differ between hot rolled and cold rolled steel due to how they’re made. Cold rolling adds more inner stress. This can limit shaping unless stress is eased by heating.

Hot rolling eases stress as it cools, but may cause slight warping from uneven shrinking. These affect how each steel acts under weight. Cold rolled steel is stiffer but more brittle. Hot rolled steel handles changing forces better.

How Do Hot Rolled vs. Cold Rolled Steel Compare in Cost, Availability, and Suitability?

What Role Does Processing Cost Play in Selecting the Right Steel Type?

Hot rolled steel costs less than cold rolled steel. It needs fewer steps and no extra finishing unless the project calls for it. For budget projects where exact sizes or smooth looks aren’t key, like general building, hot rolled steel gives great value.

Cold rolling costs more due to precise tools and slower work. But its better performance suits tasks needing high accuracy or strength.

How Do Lead Times and Supply Chains Differ Between the Two Processes?

Hot rolling plants make large batches with shorter wait times. They’re set for high-volume standard shapes like beams or plates. Cold rolling lines focus on custom or narrower products. This can mean longer wait times based on order details.

But the cold-formed steel workshop is equipped with 25 cold forming lines with a monthly capacity of 5,000 tons. This shows modern plants can handle both volume and custom needs well.

When Is It Worth Paying More for Cold Rolled Over Hot Rolled?

Pay for cold rolled steel when your project needs exact fits, like brackets, or smooth surfaces, like visible parts. It’s also worth it for higher strength in structural supports. This saves time on extra work and boosts reliability over time.

Who Is CZT and What Makes Our Solar Panel Brackets Stand Out?

Who We Are at CZT and Our Commitment to Quality

At CZT, we focus on advanced structural solutions for solar energy systems. Our plant uses many tools, from punching lines to forming mills, to meet strict quality marks. The workshop strictly follows the 6S management system. This ensures a smooth and safe workspace for all making steps.

Why We Choose Specific Grades of Hot or Cold Rolled Steel for Solar Panel Brackets

Our team picks materials based on what the project needs. For high accuracy, like interlocking bracket systems, we use cold-formed sections, such as C-Channels or Omega Types. For bigger weight support, like ground-mount frames, we may use hot rolled shapes like H-beams, depending on the design.

What Makes CZT’s Solar Panel Brackets Durable, Precise, and Reliable

We offer many products, including unistrut channel, Z Types, U Types, and Omega Types. These balance strength with easy setup across different grounds. They also resist rust through coatings added after making.

How Our Manufacturing Process Ensures Long-Term Structural Integrity

Our lines can form steel up to 10mm thick. We check quality at every step. This ensures our brackets handle weather stress for decades without bending or breaking under normal solar setup loads.

FAQ

Q: What are the main differences between hot rolled steel shapes and rolled ones?

A: Hot rolled shapes cost less and offer good strength but have rougher surfaces. Cold rolled steel gives better accuracy and finish at a higher cost. It suits detailed tasks like CZT’s solar panel brackets using C-channel structures.

Q: Which brand offers reliable solar panel brackets made from quality roll-formed steel?

A: CZT provides sturdy solar panel brackets. We use hot-rolled H-beams for load support and cold-rolled sections like Omega Types and C-Channels for renewable setups.

Q: How do I choose between hot and rolled materials when selecting solar mounting hardware?

A: Pick based on need. For exact fit and sleek looks, like roof mounts, choose CZT’s cold-rolled options. For bigger support, like ground mounts, hot-rolled beam designs give better strength and value.

Q: Are there advantages to using CZT’s C-shaped channels over other types?

A: Yes, C-shaped steel is widely used for its light weight and low cost. CZT ensures steady quality in C-channel products, fit for modular solar systems across varied grounds and weather.

Q: What top companies manufacture both Z-channel and Omega channel types?

A: CZT makes both Z-channel and Omega channel types with advanced cold forming lines. We offer flexible designs for solar systems with tight size control and a steady supply for any project size.