What Key Location Factors Drive Farm Shed Cost Differences?

How Soil Type and Terrain Affect Construction Requirements

The cost of a farm shed changes a lot depending on the ground it’s built on. Soil type and terrain play a big role. For example, soft clay or sandy soils need deep footings or strong concrete slabs to stay steady. This adds to material and labor costs. Rocky or sloped land might need extra digging or leveling, which also raises expenses.

In hilly or uneven areas, flexible mounting systems work well. They adjust to the land’s natural shape. Flexible solar mounting support is a large-span, high-clearance, multi-span structure that adapts to conditions such as undulating terrain and increased vegetation. These systems cut down on costly earthmoving. They make building possible even on tough land, saving time and money.

For instance, a farm on a rocky hillside using flexible solar mounting support avoids heavy excavation. This keeps costs lower while ensuring a solid structure.

Why Accessibility and Transport Logistics Increase Costs

Getting to the build site matters a lot for farm shed costs, especially in far-off rural areas. Moving heavy parts like H-Beam Steel or C-Purlin to remote spots can mean higher shipping fees. Poor roads or tight access for big trucks make it even pricier.

If special tools like cranes or drilling rigs are needed on-site, costs go up. These machines take time and money to transport. On the other hand, sites near suppliers or good roads save on delivery time and costs.

A farm near a main road, for example, gets materials faster and cheaper than one deep in the countryside, making the project more affordable.

The Role of Local Regulations and Permitting in Cost Planning

Rules differ by area and can push up farm shed costs. Some places have strict building codes based on wind, earthquakes, or fire risks. Meeting these rules might mean using stronger materials like Omega Steel Beams for better support or coatings that resist rust.

Permits can also add costs. In some areas, you need environmental checks or engineering reports, which bring extra fees and delays. Checking with local officials early helps avoid surprises and keeps the project on track.

For example, a farm in a windy region might need Omega Steel Beams to meet codes, adding to costs but ensuring safety and approval.

How Does Climate Impact Material Choices and Budgeting for Farm Sheds?

The Effect of Rainfall and Humidity on Structural Durability

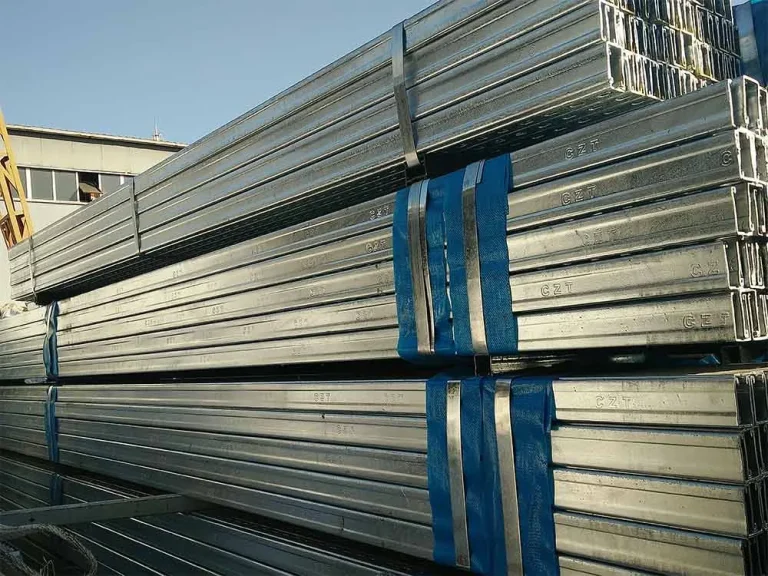

Lots of rain or humidity can rust metal sheds fast. In these conditions, picking galvanized steel parts is key to making sheds last longer and cutting repair costs. C-shaped steel is available in galvanized or painted finishes for enhanced durability.

In coastal areas, salty air speeds up rust. Using Z Steel Channel with galvanized or powder-coated finishes fights this problem. It keeps the shed strong and looking good for years.

A coastal farm using Z Steel Channel, for instance, avoids rust damage, saving on future fixes and keeping the shed sturdy.

Planning for Wind Loads, Cyclones, and Storms in High-Risk Areas

In cyclone regions, like Northern Queensland or parts in Western Australia, sheds need to endure high wind conditions. It will include the use of robust connections, like Purlin Connections that are manufactured from Q235B or Q355B having HDG surface treatment. Roofs may also need supplemental bracing using Omega Steel Beams that withstand heavy winds.

Wind-rated material construction makes sheds safe and avoids fines at the time of inspection. A shed in a cyclone-prone area equipped with these features, for example, withstands cyclones and remains standing, protecting equipment kept inside.

Adapting to Temperature Extremes: Insulation, Ventilation, and Energy Efficiency

Hot or cold regions, like inland Australia, need special shed designs for comfort and energy savings. Adding insulation panels to roofs helps control heat. Good ventilation, like ridge vents or louvered openings, keeps air moving.

Choosing light-colored roofs cuts down on heat buildup. Reflective surfaces also help keep the inside cool. Modular framing systems make it easy to add these features without losing strength.

A shed in a hot desert with insulation and light roofing, for instance, stays cooler, saving energy and keeping stored items safe.

Why Regional Labor and Supply Chain Conditions Matter in Farm Shed Pricing?

Variations in Labor Availability and Wage Rates by Region

Labor costs vary by area. Cities often have more skilled workers, keeping wages lower due to competition. Rural areas, though, might lack workers, so crews need travel or lodging pay, which raises costs.

Prefabricated parts help here. They need less on-site work. Unistrut Channel Steel is a modular & adjustable system compatible with various fittings for rapid assembly, cutting labor time.

A rural farm using Unistrut Channel Steel, for example, saves on labor costs by speeding up installation with fewer workers.

Supply Chain Disruptions and Material Price Fluctuations

Global issues, like pandemics or trade problems, can spike steel prices or delay deliveries. Areas that rely on imported materials feel this most. Working with local suppliers like CZT, who run 25 cold forming lines producing C types, Z types, Omega types, etc., ensures steady stock.

A farm using CZT’s local supply avoids delays and price jumps, keeping the project on budget and on time.

The Influence of Local Contractor Expertise on Project Budgeting

Local contractors who know the area’s climate can design sheds that last without overspending. They pick the right parts, like H-Beam Steel for heavy frames or lighter options when they work just as well.

Their know-how also speeds up permits, which is key during tight farming seasons. A contractor in a rainy region, for instance, might choose galvanized C-Purlins to save on long-term costs while meeting local rules fast.

How Can Smart Planning Reduce Farm Shed Costs in Challenging Environments?

Site Selection Strategies to Minimize Earthworks and Drainage Costs

Picking a good site with natural drainage cuts costs for grading or water systems. Avoiding flood zones also lowers insurance and repair costs.

On uneven land, like hilly farms, flexible solar mounting support systems with prestressed steel cables work well. They reduce digging while keeping the shed steady. A farm on a slope using this system, for example, saves on earthworks and builds faster.

Choosing Modular Designs to Adapt to Varying Climates Efficiently

Modular shed designs let farmers adjust to local weather without starting over. Parts like C-Purlins, Z Channels, and pre-made connections allow builds that fit hot deserts or wet tropics.

These designs speed up construction and make future expansions easy. A farm adding storage later can use the same modular parts, saving time and money.

Leveraging Government Grants or Incentives Based on Location

Many areas offer grants for farm buildings, especially those with green features like solar-ready roofs. Checking with local councils early can help farmers use these funds to lower costs.

A farm adding a solar roof with a grant, for instance, cuts upfront costs while meeting eco-friendly goals, making the shed a smart investment.

Who Is CZT, and How Do We Help You Optimize Farm Shed Cost Planning?

Our Commitment to Durable, Climate-Resilient Farm Sheds

At CZT, we focus on strong steel framing solutions for farms worldwide. Started in 2013 in Tianjin, a major logistics hub, our 28,000-square-meter factory produces 10GW of photovoltaic brackets yearly.

Our products, like fixed brackets and flexible supports, are made for tough terrains. We use high-grade Q235B/Q355B carbon steel with HDG for rust protection, perfect for harsh weather.

Recent Projects That Showcase Our Regional Adaptability

Our work shows we adapt to any region. CZT Case Studies highlight this:

- In Jiangsu Province’s humid climate, we built a farm shed with galvanized steel frames to fight moisture.

- In Gansu Province’s dry, windy desert, we used reinforced mounting systems to handle winds over 50 m/s.

- In Yunnan Province’s steep, green hills, our solar mounting system allowed building without major digging.

These projects show we deliver efficient, tailored solutions no matter the location or climate.

FAQ

Q: What factors most affect the cost of building a farm shed?

A: Soil type, terrain slope, site access, climate, material choices (galvanized vs non-galvanized), labor costs, permits, and shipping logistics.

Q: How does climate influence material selection for farm sheds?

A: Wet areas need rust-proof materials like galvanized steel. Windy zones require strong frames to handle storm forces.

Q: Can I build a farm shed on sloped land without high excavation costs?

A: Yes, flexible mounting systems with prestressed cables allow building on uneven land with less digging.

Q: Are there government incentives available for constructing farm sheds?

A: Many areas offer grants for sheds with green features like solar panels. Check local rules early to qualify.

Q: Why is modular design recommended for rural farm buildings?

A: Modular designs save time and money by allowing easy assembly and adaptation to different climates.