What Makes L Shaped Steel Brackets Essential in Structural Reinforcement?

The Role of L Shaped Steel Brackets in Load Distribution

L shaped steel brackets play a key part in spreading weight across connected building parts. Their right-angle shape lets them move forces from one side to another. This handles both up-and-down and side-to-side stress well. Such weight sharing stops stress from building up in one spot. Over time, this prevents material wear or breaks. By fixing beams, columns, or panels at important joints, L shaped brackets make sure weight spreads evenly across the frame. This boosts the structure’s strength and safety.

In uses like solar panel mounts or mezzanine floor supports, C-shaped or Z-shaped channels offer a good strength-to-weight balance. L brackets act as vital links here. They keep alignment and weight steady. C-shaped steel, also known as C-Purlin or C-Channel, is a cold-formed steel section with a clear “C” shape.

Enhancing Joint Stability with L Shaped Steel Brackets

Adding L shaped steel brackets greatly improves joint steadiness in building setups. These brackets strengthen meeting points between parts like beams and columns. They provide extra space for bolts and support. This cuts down movement under changing loads, like wind or shakes. Such steadiness is key to keeping structures solid over time.

When paired with other well-made parts, like Steel Welding Parts – Precision-Fabricated Components for Industrial Applications, L brackets form strong connections. These resist twisting and side forces. This matters a lot in modular or pre-made buildings, where joint trust directly affects safety.

Preventing Structural Failures Using Steel Bracket Supports

L shaped steel brackets guard against building failures by strengthening weak spots where materials meet or end. In cases with heavy weights or side forces, like in industrial platforms or tall buildings, these brackets give critical support. They prevent bending, cracking, or splitting of materials.

They work well with bigger parts like H-Beam Steel. This steel, also known as H-Shaped Steel, has an “H” shape and offers great resistance to bending and pressure. With well-planned bracket supports, the whole system gains better safety and a lower risk of major failure.

How Do L Shaped Steel Brackets Improve Seismic Resistance in Buildings?

The Function of L Shaped Brackets in Earthquake-Prone Areas

In areas prone to quakes, L shaped steel brackets are vital for making buildings tougher. These brackets take in and spread quake energy. They anchor key joints and reduce movement during ground shakes. Their ability to make tight mechanical links helps keep the building’s shape and lineup, even under strong side forces.

When set up right with rust-proof materials, like galvanized steel, they stay useful for the building’s whole life, even after many shakes.

Reinforcing Wall-to-Floor and Beam Connections for Seismic Safety

One weak spot during quakes is where walls meet floors or beams join columns. L shaped steel brackets strengthen these spots by adding extra anchor points. These resist side shifts. By tying up-and-down and side-to-side planes more firmly, they lower the chance of partial falls or misalignments that harm safety.

This pairs well with Unistrut Channel Steel, a high-quality slotted metal framing system for modular buildings. When used with L brackets, they form flexible yet tough frames. These can take quake shocks without lasting harm.

Examples of Seismic Applications Using L Shaped Steel Brackets

Real cases show how well these brackets work in quake-proof projects. For example, commercial buildings often use L shaped steel brackets in hanging ceiling systems. This stops parts from falling during shakes. In setups like tunnels with Omega Steel Beam, a high-performance steel part with an Ω-shaped (Omega-shaped) cross-section, these brackets steady curved parts against twisting stress from quake waves.

Where Are L Shaped Steel Brackets Commonly Used in Construction Projects?

Residential Construction: Securing Frameworks and Corners

In home building, L shaped steel brackets are often used to fix wood or metal frames at corners and joints. They strengthen roof trusses, wall studs, or floor joists made from materials like Z Steel Channel – High-Strength Structural Framing Solution. These brackets ensure the frame stays steady during building and use.

They also make setup simple. They work with standard screws and bolts. This helps builders finish fast without losing strength.

Commercial Buildings: Supporting Heavy Structural Elements

Commercial buildings need higher weight handling due to wide spans and heavy use. Here, strong L shaped steel brackets support HVAC mounts, mezzanine floors, stairs, and curtain walls. When used with H-Beam Steel or welded setups made from carbon steel (Q235B, Q345B) or high-strength low-alloy (HSLA) steel, these brackets build tough systems. They handle steady weights and changing stresses, like wind force.

Infrastructure Projects: Integrating Brackets into Bridges and Tunnels

Big projects like bridges and tunnels gain a lot from rust-proof L shaped steel brackets. These parts fit into cable trays, light mounts, sign supports, and access platforms in tunnels. Such areas face shaking, wet conditions, and temperature changes.

Their use pairs well with profiles like Omega Steel Beam, which give strong twist resistance. Together, they form very steady frames for civil engineering settings.

Why Are Material Quality and Design Critical for L Shaped Steel Bracket Performance?

Comparing Low-Grade vs. High-Grade Steel in Structural Applications

An L shaped steel bracket’s work depends a lot on its material makeup. Low-grade steels may bend under stress or rust over time. This harms safety. High-grade steels like Q235B or Q345B give better strength and stretch. They suit tough uses. Made from carbon steel (Q235B, Q345B HDG steel), these materials ensure long-term trust, even in changing conditions.

Importance of Corrosion Resistance and Surface Finishing

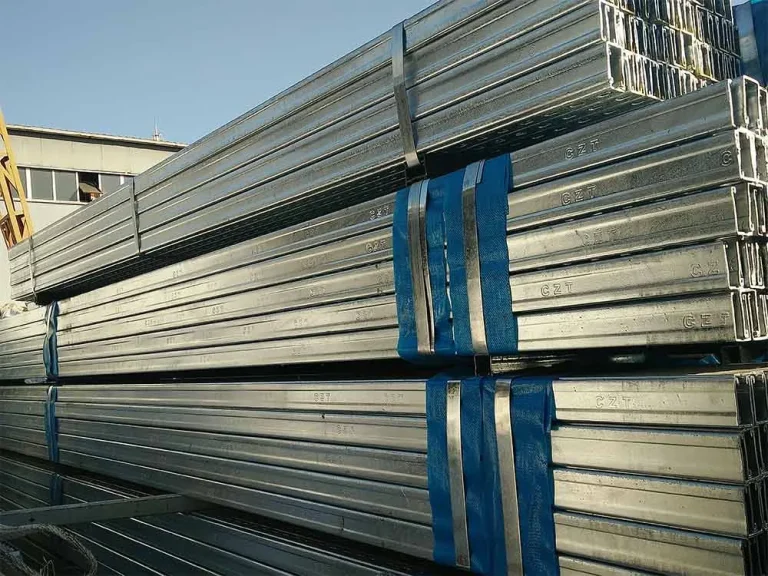

Rust resistance greatly lengthens a bracket’s use life, especially in wet or chemical-heavy spots. Hot-dip galvanizing (HDG), powder coating, or epoxy treatments guard against rust on bracket surfaces. As noted in CZT product details, like our solar mounting systems: Surface Treatment: HDG, Pre-galvanized, or as you require. These finishes make our products fit for coastal areas where salt rust is common.

Design Variations and Their Impact on Load-Bearing Capacity

Design points like thickness (usually 1mm–50mm), bend accuracy, and hole placement affect how much weight an L bracket can hold. Custom options let engineers shape brackets for specific needs, from light home use to heavy industrial tasks. Detailed CAD drawings from makers like CZT help with this.

What Does CZT Offer in High-Performance L Shaped Steel Brackets?

Who We Are at CZT: Commitment to Safety and Engineering Excellence

At CZT, we focus on high-performance photovoltaic mounting systems. We started in 2013 in Tianjin, northern China’s biggest port city. Our 28,000-square-meter plant makes up to 10GW yearly. We produce fixed mounts, trackers, carports, and key parts like precision-made L shaped steel bracket solutions.

Our Product Range: Precision-Made Brackets for Structural Use

Dimensions, Load Ratings, and Material Specifications

Our L shaped steel bracket products use cold-forming tech from top-grade carbon steels like Q235B/Q345B. Thickness goes up to 10mm based on need.

Custom Fabrication Options for Project-Specific Requirements

Our laser cutting and cold bending workshop has CNC machines. We offer full custom work, from early designs to large runs, to meet exact building needs worldwide.

Coating Technologies for Durability in Harsh Environments

We use hot-dip galvanizing (HDG), pre-galvanizing, and powder coating options tailored to client needs. These ensure long-term protection against the weather over decades.

Installation Guidelines and Technical Support Services

Our global service team gives full documents, like CAD drawings and setup guides. We also offer pre-assembly at our packing workshop. This ensures smooth use in markets worldwide.

FAQ

Q: Which brand offers reliable L shaped steel bracket products?

A: CZT gives trusty L shaped steel bracket solutions. They’re backed by ISO-certified making and use high-grade carbon steels like Q235B/Q345B.

Q: How do I choose the right L shaped steel bracket for my construction project?

A: Look at material grade (Q235 vs Q345), rust protection (HDG vs painted), and thickness for your weight needs. Ask CZT’s team for custom advice.

Q: Are CZT L shaped steel brackets suitable for seismic applications?

A: Yes. Our precision-made L shaped brackets strengthen beam-column joints in quake-prone areas. They hold up under changing loads.

Q: What’s better for joint reinforcement—L shaped bracket vs welding only?

A: Welding makes strong bonds. But Steel Welding Parts and bolted L-shaped bracket supports often give better backup against issues like shear slip or cracking.

Q: Who are the top manufacturers offering custom fabrication of L shaped steel brackets?

A: CZT stands out with OEM services, mold design per drawing, laser cutting accuracy to ±0.2mm, and fast delivery, even for small orders.