Carport Photovoltaic Systems Market Trends Under Rising Global Energy Costs

Growth Drivers in the Carport Photovoltaic Bracket Market

Carport photovoltaic bracket market growth is accelerating as businesses respond to rising electricity prices and increasing sustainability mandates. The growing need for dual-purpose infrastructure encourages companies to use parking areas for solar generation, driving higher demand for reliable carport mounting structures. As more organizations prioritize power-neutral operations, the bracket market benefits from a shift toward steel systems with longer service life and improved corrosion protection.

How Energy Price Inflation Accelerates Commercial Adoption of Solar Carports

Energy price inflation accelerates the adoption of carport photovoltaic systems because companies want stable, long-term electricity costs. Solar generation installed above parking lots reduces dependence on volatile grid tariffs and offsets peak-hour electricity consumption. With electricity costs projected to increase steadily in many regions, solar carports become a practical hedge against price uncertainty and a tool for operational cost control.

Why Businesses Seek Energy Independence Through Carport PV Deployment

Businesses seek energy independence through carport PV deployment to achieve predictable energy budgets and meet sustainability commitments. A well-designed carport photovoltaic system can supply a substantial share of a facility’s daytime electricity use while turning an underutilized asset into a power-producing structure. As a result, carport PV has become central to long-term energy strategies for logistics centers, industrial parks, and commercial buildings.

Core Engineering Factors That Improve Carport Photovoltaic System Performance

Optimizing Solar Module Tilt, Orientation, and Row Configuration

Optimizing solar module tilt, orientation, and row spacing is essential for maximizing the performance of carport photovoltaic systems. Proper tilt angles increase annual sunlight capture, while row spacing prevents inter-row shading during low-sun seasons. Engineering teams use site-specific irradiation data to define angles that balance production and structural feasibility.

Structural Steel Material Selection for Long-Term Output Stability

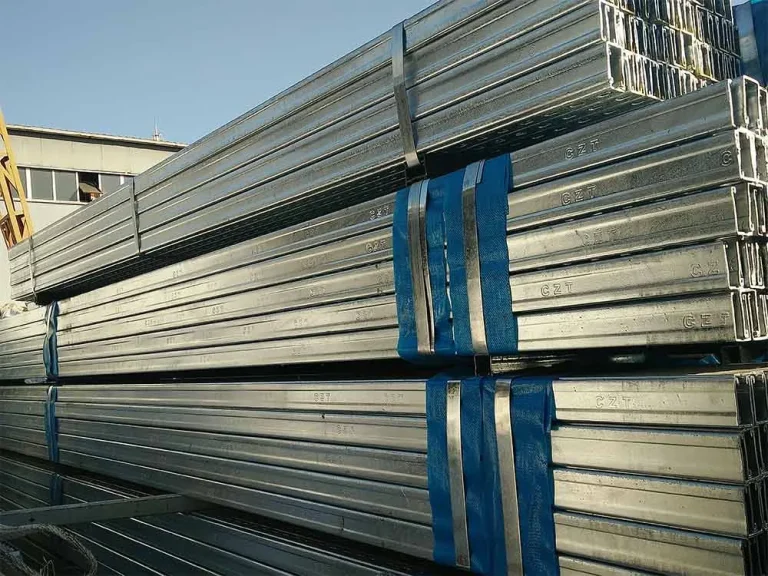

Structural steel material selection directly influences the long-term performance of carport photovoltaic installations. Carbon steel in grades such as Q235B and Q355B provides excellent mechanical strength and is widely used in commercial carport frames. When combined with proper surface treatments, these materials resist deformation and corrosion over decades of service, helping preserve consistent energy output.

Comparing Carbon Steel, Hot-Dip Galvanized Steel, and Zn-Al-Mg Coatings

Looking at carbon steel, hot-dip galvanized steel, and Zn-Al-Mg coatings helps match tough needs to site weather. Hot-dip adds a thick guard layer for long outside time. Zn-Al-Mg fights rust better in sea or wet spots. The right coating pick keeps building steadily. It guards the full 25-year life of the PV system.

Wind Resistance, Snow Load Capacity, and Their Impact on Energy Yield

Wind hold and snow weight handle affect the carport system’s trust and power make. Strong winds or thick snow can harm parts if not built right. Strong beams, exact purlins, and tough fasteners keep panels fixed. They go on making power in bad weather.

Electrical System Optimization for Enhanced Conversion Efficiency

Tuning the electrical system lifts change efficiency in carport photovoltaic setups. Good wire paths, top connectors, and planned string setups cut send losses. In business uses, inverters with good rates and smart watch tools keep output even. They ease upkeep over the years.

Maximizing ROI Through Intelligent Energy Management and System Integration

Reducing Operational Electricity Costs with Solar Carport Generation

Reducing operational electricity costs is one of the strongest ROI drivers for carport photovoltaic systems. By generating clean energy at the point of consumption, businesses reduce their grid dependence and protect themselves from pricing volatility. Over time, these cost savings accumulate and shorten the payback period of the installation.

Integrating EV Charging Infrastructure to Increase System Value

Adding EV charge setups raises the carport PV system’s worth. It aids electric car use in business spots. Solar power for charging cuts the grid pull. Firms can grow charge spots without high power bills. This makes parking ready for the future.

Utilizing Incentives, Net Metering, and Peak-Shaving Strategies

Using aids, net-meter rules, and peak-cut plans boosts ROI a lot. Governments give tax breaks or funds for green setups. Net-meter lets extra power make money credits. Peak-cut lowers high-price use. This lifts long-run ROI more.

Transforming Parking Lots into High-Efficiency Energy Assets

Turning parking lots into strong energy spots adds value to sites with big paved areas. Solar carports mix car shade with clean power generation. This aids green aims and the best use of land for groups wanting the most from their space.

Practical Planning Considerations for Cost-Optimized Carport PV Deployment

Site Assessment: Shading, Orientation, Soil, and Structural Constraints

Site check shapes carport PV setups’ win and cost savings. Engineers look at shade ways, sun paths, ground state, and parking shape. These set the right carport kind, post gaps, and base plan. They ensure good work and build trust.

Installation Efficiency Through Pre-Assembly and Modular Mounting Components

Set up speed rises with pre-made parts and block mount plans. At CZT solar, we pre-build key parts of our Type A Carport, Type B Carport, and Type C carport builds. This eases setup and cuts site work time. The way lowers costs. It also limits upset in busy parking.

Long-Term O&M Strategies to Preserve ROI and System Stability

Long-run care plans keep ROI by holding the carport photovoltaic system steady. Regular checks, clean times, and live watch tools spot small problems early. They stop output harm. A forward care flow aids system trust and long-term asset value.

CZT Solar Carport Solutions: Engineering Strength, Material Quality, and Customization

Why CZT Solar Uses Q235B/Q355B Carbon Steel for Structural Reliability

에 CZT 태양, we pick Q235B and Q355B carbon steel to build trust in business carport photovoltaic systems. These mix high pull strength with shape ease. So, we make tough beams and posts that meet hard load needs.

CZT Solar Carport Series (Type A, B, C): Structural Designs for Different Site Conditions

Our Type A Carport, Type B Carport, and Type C carport builds fit varied site plans and weather. Type A gives a simple, even shape for office parking. Type B holds wide gaps needed in factory areas. Type C fits bendy setups for odd parking shapes.

Manufacturing Capabilities: Cold-Forming Lines, HDG Treatment, and Precision Welding

Our make skills cover cold-form lines, top weld systems, and full HDG surface care steps. These keep the product even in quality. They give long guards for steel parts in outside spots.

Customizable Carport Photovoltaic Bracket Systems for Industrial and Commercial Projects

We give bend-to-fit carport photovoltaic bracket systems for factory, business, and public site jobs. Our team tunes sizes, coatings, purlin gaps, and base kinds to fit buyer needs and local building rules.

How CZT Solar Ensures High Load Capacity, Corrosion Resistance, and Long Service Life

We make sure of high load hold, rust fight, and long work life with exact build, top materials, and tight quality check. These let our carport photovoltaic systems work steadily over their 25-year lifespan.

자주 묻는 질문

Q: What factors determine the best carport photovoltaic system for commercial use?

A: The best carport photovoltaic system depends on structural material strength, surface coating durability, foundation type, and energy-generation needs. At CZT solar, we design Type A, B, and C carport systems to meet varying site conditions and project requirements.

Q: How to choose the right carport photovoltaic bracket structure?

A: Choosing the right bracket structure requires evaluating wind load, snow load, corrosion exposure, and parking layout. CZT solar offers customizable steel bracket solutions that adapt to these conditions while maintaining long-term reliability.

Q: Which brand provides reliable carport photovoltaic systems for large facilities?

A: Reliable performance comes from a brand with engineering expertise, material quality, and manufacturing capacity. CZT solar provides high-strength carbon steel carport systems backed by advanced cold-forming, welding, and HDG treatment processes.

Q: What is the difference between single-row and multi-row carport photovoltaic systems?

A: Single-row systems are ideal for small or symmetrical parking areas, while multi-row systems support large-scale facilities requiring higher energy output. CZT solar develops both configurations within our Type A, B, and C product series.

Q: How to compare different carport photovoltaic materials for long-term durability?

A: Durability comparisons focus on steel grade, corrosion-resistant coatings, and environmental conditions. CZT solar uses Q235B/Q355B carbon steel with HDG and optional Zn-Al-Mg coatings to maximize lifespan and structural integrity.