何がH形鋼の高強度重量比をそんなに有価にするのでしょうか?

H 形鋼が負荷軸受性能を最適化する方法

H型鋼鉄Hビームまたは広いフランジビームとしても知られていますが、重いものを持ち上げるために素晴らしい特別な形状を持っています。その平らな側面と直立した中央部分は、曲がりや曲がと戦うのに役立ちます。このセットアップは、それ’最も必要なsは、ビームを軽く保つが、強く。したがって,H形の鋼鉄は,曲がるか,断つことなく,長いストレッチで大きな負荷を運ぶことができます.

現代建設における構造効率が重要な理由

今日’建設作業、効率は少しで多くをすることを意味します。H形の鋼鉄’高い強度重量比により,製造業者はより軽いフレームを使用することができます.これは基礎からの圧力を取り消し、出荷を容易にし、仕事を加速します。高い建物、橋、工場の場合は、より多くのオープンスペースと廃棄物の減少を意味します。

H型鋼の強度メトリックスと他の構造材料の比較

木やコンクリートに比べて,H形鋼は引き出す力と押す力の両方でより強いです.木は小さな仕事のために良いですが’t 鋼鉄のように安定したまたは防火。コンクリートのハンドルはよく押しますが、引き出すために追加の助けが必要です。H型鋼は両方を1つの部分で行い、風や地震のような厳しい条件に最適です。

H形鋼の設計の柔軟性はどのように建築的可能性を高めますか?

複雑な建物設計におけるH型鋼の役割

製造業者はH型鋼を選ぶのは、ファンシーなデザインやオープンレイアウトでうまく機能するからです。空港,スタジアム,ショップなどの場所に大きなエリアを作ることができます.通常のサイズにより、他の建物部品と簡単に一致できます。

様々な構造要件にH形鋼を適応する

Hビームはあらゆるサイズと厚さで提供され,軽いフレームから重工業用セットアップまですべてに適しています.彼らはプランに応じて、柱として高く立つか、ビームとして平らに躺ることができます。また、コンクリートの板やトラスのようなものともよく組み合わせています。

H形鋼鉄プロフィールで利用できるカスタマイズオプション

鋼鉄ワークショップには,特定の仕事のためのカスタムHビームを含む多くの鋼鉄製品を作る25の形成ラインおよび15の鋼鋼鋼鋼鉄工場があります.ワークショップは6Sマネジメントシステムに固執し,現地および世界の基準を満たす最高品質の作業を確保します.

耐久性と長寿がH形鋼構造の主要な利点である理由は?

H型鋼鉄フレームワークにおける環境圧力への抵抗

H型鋼は自然に害虫,木木造構造を破壊するものである害虫,木木木HHH型鋼は害虫,HHH型鋼は自然に害虫,HHH型鋼は害虫,HHHH型鋼は自然に害虫,コーティングやコーティングまたはコーコーティングまたはコーコーコーティングまたはコーコーティングまたはコーコーコーティングまたはコーコーティングにより、コーコーコーティングやコーコーコーティングまたはコーコーコーティングまたはコーコーコーティコーティングまたは

H形鋼を使用する建物の長期的な構造的完整性

木やコンクリートとは異なり,時間とともに扭曲したり,弱まったりする可能性があるが,H形鋼は何年も重量の下で固体に保持されます.これは、あなた’チェックまたは修正する必要があります。

長期使用のためのメンテナンス要素

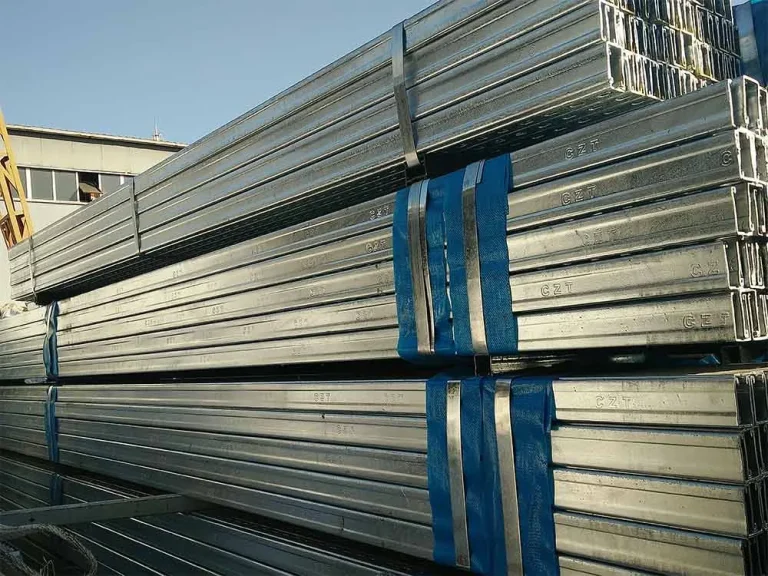

私たちはQ235BおよびQ345BHDG鋼を使用します。これらのタイプはCZTによって使用され、磨損や天候に耐えます。表面処理は,熱熱熱熱熱熱熱熱熱熱熱熱熱表面処理は,熱熱熱熱熱熱熱表表面処理は,メンテナンス要件を低減らし,長期的な構造的メンテナンメントコストを減らすのに役立ち向けます.

H型鋼はどのような方法で建設の速度と効率を向上させますか?

建設プロセスの簡素化を行う

プレファブリケーションはHビームが制御された場所で現場外で作られることを意味します。ワークショップには2台のレーザー切断機と3台の曲げ機があり、特別な注文でもビームを迅速にWhip Upすることができます。

簡素化された組み立てによる現場での労働削減

彼らの正規な形と正確なサイズで、プレファブリックHビームdon’現場で多くの調整が必要です。これにより、作業時間を節約し、高い作業を削減することによって建物をより安全にします。

プロジェクトタイムラインとスケジューリング H形鋼を使用する利点

より速い建設は、プロジェクトがより速く終わることを意味し、時間がお金であるときは大切です。CZTのようなサプライヤーは,各地域で時間通りに配達し,計画を順調に維持するのに役立ちます.

H形鋼の使用のコスト効果性はプロジェクト予算にどのように影響を与えるのでしょうか。

メンテナンスの削減によるライフサイクルコストの低減

Steel’sの堅さは木やコンクリートに比べて修正が少ないことを意味します。これは時間とともに現金を節約するためのスマートなピックをH形の鋼にします。

最適な重量分布による材料の節約

高い強度重量比のおかげで,H型鋼は仕事を完了するために材料を少なく使用し,材料コストを節約します.軽い荷物も運送費を削減します。

予測可能なパフォーマンスを持つ予算計画の利点

エンジニアはH形のsteel’を見つけることができます;シンプルな数学での負荷能力。これは計画の推測を削減し、驚きの追加コストを削減します。

持続可能性はなぜH形鋼を選ぶための成長する理由ですか?

構造鋼Hビームのリサイクル性と環境影響

鋼鉄は最もリサイクルされた材料の一つです。ほとんどの構造鋼はリサイクルされた内容を持ち、建物が崩壊した後に強さを失うことなく再利用できます。

H型鋼の生産および使用におけるエネルギー効率

鋼鉄製造の新しい方法は、古い方法よりも1トンあたりのエネルギーを減らします。軽い構造はまた,船舶や建物の間にエネルギーを節約します.

持続可能な材料で緑の建築基準を満たす

リサイクル可能な鋼鉄を使用することで、プロジェクトがLEEDのようなグリーン基準を満たすことができます。これは現在、公共建物と民間建物の両方にとって大きな問題です。

構造鋼Hビームの耐火性は何ですか?

治療された構造鋼部品の防火評価能力

防火ペンキや浸透層のようなコーティングでは,H形鋼はコーティングに応じて2時間以上持続する厳しい防火規則を満たすことができます.

防火設計要素による建物の安全性向上

高速に燃える木や熱で裂くことができるコンクリートとは異なり、処理されたH型鋼は火で長く耐える。消防士に行動する時間が多く、消防士に行動する時間が多くなります。

構造鋼Hビームは代替フレームワーク材料とどのように比較されますか?

コンクリート、木材、H形鋼の性能の違い

コンクリートは押すのに強いが、追加の助けなしで引くのに弱い。木は曲がるが、容易に燃える。H形の鋼鉄は両方のバランスを取り、あらゆる種類の仕事のためによく動作します。

異なる建物タイプにおける適切性の評価

長いスパンを必要とする高いオフィスビルから防防防耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐耐長長長長長長いスパンを必要とする高い高い高非常に柔軟です。

構造鋼Hビームを指定するときに何を考慮すべきですか?

建設用の標準的な寸法と等級

標準サイズはHビームを異なるサプライヤーと働かせます。Q235B/Q355Bのようなグレードは,地震や雪のような地域の条件に基づいて安全な設計のための強度レベルを設定します.

ビーム選択に影響を与えるエンジニアリング要因

スパンの長さ,負荷のタイプ (ポイントまたはスプレッド),接続方法 (ボルトまたは溶接),および偏移は,すべてのガイドビームの選択肢を制限し,天井の高さや柱間隔などの設計ニーズを制限します.

Hビームの多様なアプリケーションをどこで見ることができますか?

構造鋼ビームの商業,産業,住宅用途

H ビームは倉倉庫ラックから橋の支えまですべてで使用されています。CZTはOEM&を提供します製品のようなサンプルの利用可能性 OEMレーザー切断部品 & 溶接部品これらの用途のために作られています。

H形フレームワークを活用した高性能建物の例

ソーラーマウントシステムはH形のsteel’を示します;Sの強さ。 「 The CZT 1軸追跡システム 1軸で動くソーラーパネルを持ち、216km/hと1.4kn/m2までの雪/風負荷を処理する堅いHビームフレームワークで構築されています。

CZTは誰であり、我々は構造鋼の分野で何を提供しますか?

構造鋼Hビームの製造における品質への私たちのコミットメント

CZTの精密製造基準

ワークショップは6S管理システムに従って、仕事を滑らかで正確に保ちます。

材料認証とコンプライアンス

認証:ISOおよびSGSは私達のプロダクトが世界規格を満たすことを示します。

在庫範囲:サイズ,等級,および注文

私達はOEM &を提供しますサンプル:私たちの在庫全体で利用可能なサービス。

表面処理と腐食保護オプション

オプションには,HDG (ホット・ディップ・アルバニズ),プリ・アルバニズ,または仕事の必要性に基づくカスタム処理が含まれています.

大規模配達のための物流サポート

CZT’国際サービスチームは,世界的な顧客のためにカスタマイズされたソリューションを提供し,タイム上の配達を確保します.

FAQについて

Q:なぜIビームの上でH形の鋼を選ぶのでしょうか。

A:H形の鋼鉄にはよりよい負荷の拡散のためのより広いフランジがあり、特に曲がりの下で、多くの仕事のためにより有用です。

Q:H形の鋼鉄は外にQ:Q Q Q:Q Q:Q Q Q Q Q:H形の鋼鉄はQ Q Q:Q Q Q Q:H形の形の鋼鉄はQ Q Q Q Q Q

A: はい。熱浸熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱熱

Q:私はどのように正しいHビームサイズを選択しますか。

A: サイズはスパンの長さ、負荷のタイプ、および偏移の制限によって異なります。計画中にエンジニアに相談して正しいものを選ぶ。

Q: Hビームは地震に優れた地域に適していますか?

A: はい。その柔軟性は,地震中にエネルギーを吸収し,硬い材料と比較して崩壊リスクを低減します.

Q: 建物が崩壊した後、H型鋼はリサイクルできますか?

A: はい。鋼鉄は多くのリサイクルサイクルを通じて強さを維持し、非常に緑色な材料になります。