Pourquoi les formes en acier inoxydable sont-elles essentielles dans les structures résistantes aux tremblements de terre?

Comment les profils en acier inoxydable améliorent-ils la flexibilité structurelle?

Les formes en acier inoxydable, comme les canaux et les poutres, sont essentielles pour les bâtiments dans les zones sujettes aux tremblements de terre. Ils se plient sans se casser. Cela aide les bâtiments à gérer les secoussements en toute sécurité. Il leur permet d'absorber et de libérer l'énergie des tremblements de terre. Contrairement aux matériaux rigides qui peuvent se fissurer sous la force, les pièces en acier inoxydable se plient et reviennent à leur forme. Cela permet de maintenir les dommages faibles pendant le tremblement de terre.

L'acier inoxydable devient également plus dur sous des contraintes répétées. Le tremblement de terre provoque des forces d'aller-et-retour. Ces forces testent les pièces de construction. Acier inoxydable’ sa résistance le rend bon pour les composants tels que les cadres, les supports et les connecteurs. Ces pièces doivent rester solides à travers de nombreux cycles de stress. Cela maintient le bâtiment en sécurité.

Qu'est-ce qui rend l'acier inoxydable un matériau idéal pour les zones sismiques?

L'acier inoxydable combine une construction solide avec une résistance à la rouille. Cela rend bon pour les zones de tremblement de terre. Il s'étend sous de lourdes charges sans éclater. Cela donne un avertissement avant de casser. La capacité de pliage ajoute de la sécurité. Le matériau fonctionne également bien dans différents temps et températures.

Dans les zones de tremblement de terre près des mers ou des endroits humides, la résistance à la rouille est essentielle. L'acier inoxydable reste fiable au fil du temps. Elle résiste dans des conditions difficiles. Les alliages chrome-nickel élevés ajoutent une résistance supplémentaire. Ils s'assurent qu'il résiste à des paramètres difficiles sans perdre d'énergie.

Comment les récents tremblements de terre ont-ils mis en évidence le besoin de matériaux plus forts?

Les récents tremblements de terre dans le monde ont montré des défauts dans les matériaux de construction courants. Les ponts tombés, les bâtiments pliés et les bases fissurées proviennent souvent de matériaux faibles. Ces échecs ont conduit les constructeurs à prendre des options plus fortes. Les formes en acier inoxydable sont l'une de ces options. Les nouvelles règles de construction soutiennent désormais leur utilisation.

Les bâtiments avec des supports en acier inoxydable font mieux en cas de tremblement de terre. Ils ont moins de dégâts. Ils ont besoin de moins de réparations que celles faites en acier ou en béton ordinaire. Cela montre l'acier inoxydable’ rôle dans le renforcement de la sécurité. Cela réduit également les coûts de réparation.

Les formes en acier inoxydable peuvent-elles résister aux vents d'ouragan?

Quel rôle jouent les sections en acier inoxydable dans la résistance à la charge au vent?

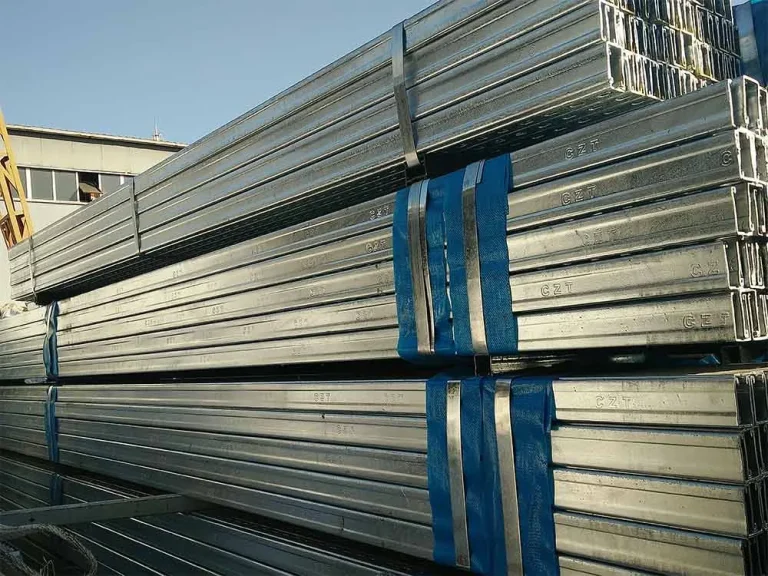

Sections en acier inoxydable, comme H acier poutresLes canaux C et Z aident les bâtiments à résister aux vents forts. Leurs formes répartissent les forces latérales de manière uniforme. Cela empêche l'effondrement. Ces profils résistent à la flexion et au torsion lors des vents forts. Les ouragans apportent souvent de tels vents.

Ils sont utilisés dans les murs rideaux, les supports de toit et les ancres. La force est essentielle dans ces domaines. L'acier inoxydable reste stable sous les forces du vent changeantes. Cela assure la sécurité des bâtiments. Cette fermeté assure la sécurité pendant les tempêtes.

Comment fonctionnent les cadres en acier inoxydable pendant les tempêtes de catégorie 5?

Les tempêtes de catégorie 5 entraînent des pressions de vent intenses. Ces pressions testent la résistance du bâtiment. Les cadres en acier inoxydable font bien. Ils ont une construction solide et résistent à l'usure. Contrairement à l'aluminium ou à l'acier doux, qui peut se plier ou rouiller, l'acier inoxydable conserve sa forme et résiste aux vents salés pendant de longues périodes. Il évite les dommages.

Par exemple, CZT’ s structure de panneau solaire en acier au carbone est conçu pour des charges éoliennes allant jusqu'à 216 km/h. Il montre comment les profils métalliques supportent les forces des ouragans. La conception intelligente assure que ces cadres restent fiables. Ils protègent les bâtiments et leurs pièces.

Quels éléments de construction bénéficient le plus du renforcement en acier inoxydable?

Les pièces clés de construction qui bénéficient de l'acier inoxydable comprennent:

- Trausses de toit

- Bouchons muraux

- Cadres de fenêtre

- Ancres de fondation

- Supports de montage de panneaux solaires

Ces pièces font face à des conditions météorologiques et à un stress constant. L'acier inoxydable résiste à la rouille. Cela prolonge leur vie. Cela réduit les coûts d'entretien. Ce renforcement maintient les bâtiments fermes dans des conditions difficiles.

Comment les formes en acier inoxydable aident-elles à protéger les bâtiments des inondations et des dommages causés par la corrosion?

Pourquoi la résistance à la corrosion est-elle cruciale dans les régions sujettes aux inondations?

Les zones sujettes aux inondations exposent les bâtiments à l'eau. Cette eau contient souvent des sels ou des produits chimiques. Ces vitesses rouillent. Acier inoxydable’ s couche protectrice arrête la corrosion. Ce bouclier maintient le matériau fort. Il reste solide même si mouillé pendant de longues périodes.

Cette caractéristique est essentielle pour les bâtiments sûrs. Les hôpitaux ou les écoles près des rivières ou des côtes en ont besoin. Acier inoxydable’ La résistance à la rouille assure que les structures restent fermes pendant les inondations. Cela réduit les risques.

Qu'est-ce qui fait de l'acier inoxydable un investissement à long terme contre l'exposition à l'humidité et au sel?

Acier inoxydable’ Sa force durable vient de son maquillage. Il contient du chrome supérieur à 10,5 %. Cela forme une surface auto-fixante. Il résiste aux dommages causés par l'eau ou le sel. Dans les endroits où d'autres métaux s'usurent rapidement, l'acier inoxydable reste fort.

Prendre des pièces en acier inoxydable permet d'économiser de l'argent au fil du temps. Cela réduit les réparations ou les remplacements. Ceci est essentiel dans les zones humides ou salées. Il fait de l'acier inoxydable un choix intelligent pour les bâtiments durables.

Comment l'intégrité structurelle se maintient-elle après un contact prolongé avec l'eau?

L'acier inoxydable conserve sa résistance après une longue exposition à l'eau. Les inondations ou les ondes de tempête provoquent cette exposition. Contrairement au bois, qui se déforme, ou au béton, qui se fissure, l'acier inoxydable résiste aux dommages. Il évite la rouille. Cela maintient sa capacité à porter du poids.

Cette fiabilité assure la sécurité des bâtiments après les inondations. L'acier inoxydable assure que les pièces clés restent solides. Il soutient la sécurité et le fonctionnement dans les zones sujettes aux inondations.

Les formes en acier inoxydable sont-elles efficaces dans les zones sujettes au feu?

Quelle est la capacité de résistance à la chaleur des composants en acier inoxydable?

L'acier inoxydable, en particulier les types austénitiques, supporte bien la chaleur élevée. Il reste fort à des températures allant jusqu'à 800 ° C (1472 ° F). Cela le rend bon pour les pièces anti-incendie. Les escaliers ou les supports sont des exemples.

Son faible transfert de chaleur ralentit la propagation du feu dans les bâtiments. Cela aide à contenir les incendies. Il aide à l'évacuation sûre et à la lutte contre les incendies. Acier inoxydable’ La résistance à la chaleur augmente la sécurité incendie.

Comment maintenir la force à des températures extrêmes ?

Acier inoxydable’ sa structure stable empêche l'affaiblissement rapide de la chaleur. Contrairement à l'acier au carbone, qui perd beaucoup de résistance à 600 ° C (1112 ° F), certains types d'acier inoxydable conservent jusqu'à 70% de leur résistance. Cette durabilité permet plus de temps pour l'évacuation. Il aide également à répondre aux urgences.

Cette performance garantit que les bâtiments restent partiellement intacts lors des incendies. Acier inoxydable’ sa tolérance thermique en fait un choix fiable pour les pièces structurelles vitales.

De quelle manière les structures en acier inoxydable soutiennent-elles les normes de sécurité incendie?

L'acier inoxydable ne brûle pas. Il ne dégage pas de fumées nocives lors des incendies. Cela répond aux règles mondiales de sécurité incendie. Ces règles exigent une propagation faible de la flamme et une fumée minimale. Il soutient la conformité dans les bâtiments tels que les bureaux, les centres de transport et les usines.

Il fonctionne bien avec les systèmes de protection incendie. Le revêtement ou l'isolation sont des exemples. Ces systèmes reposent sur des cadres métalliques robustes. Ils restent stables en cas d'urgence incendie.

Qui est CZT et comment ses produits en acier inoxydable renforcent-ils la construction résistante aux catastrophes?

Qui sommes-nous chez CZT

Fondée en 2013, CZT est basée à Tianjin. C'est la Chine’ La plus grande ville portuaire du Nord. L’entreprise soutient l’industrie photovoltaïque. Il gère la recherche, la production, les ventes et la gestion de projet. Ses installations de 28 000 mètres carrés stimulent l’innovation. Il répond aux besoins mondiaux avec des solutions fiables.

Ce qui distingue nos formes en acier inoxydable dans l'industrie

Profils conçus avec précision pour des performances maximales

CZT’ s atelier d'acier formé à froid a 25 lignes de production. Ils font des profils comme C Canal en aciercanal en acier Z et canal Unistrut. Chacun est soigneusement conçu pour la fiabilité. Ils gèrent le stress des tremblements de terre ou des tempêtes. Cette conception minutieuse assure une performance constante dans des conditions difficiles.

Alliages chrome-nickel élevés pour une durabilité supérieure

CZT utilise des alliages chrome-nickel élevés dans ses produits. Ces alliages résistent à la rouille. Ceci est essentiel dans les zones côtières avec des typhons ou de l'eau salée. Cette résistance assure des performances durables dans des climats difficiles.

Fabrication sur mesure pour répondre aux codes de construction régionaux

CZT’ s global team propose des solutions personnalisées. Ils répondent aux normes de séisme ou d'ouragan. La société adapte les pièces aux règles locales. Ses services OEM sont soutenus par des certifications ISO. Cela garantit la qualité et la conformité.

Testé et certifié pour les applications météorologiques extrêmes

CZT’ Les systèmes de montage sont testés pour des conditions difficiles. Ils gèrent des charges de vent jusqu'à 216 km/h et des charges de neige de 1,4 kn/m². Ils viennent avec une garantie de 15 ans. Ces tests assurent la fiabilité dans les zones sujettes aux catastrophes.

Spotlight sur notre système de montage solaire

Conçu en acier inoxydable de haute qualité pour la longévité

CZT’ Les structures de montage solaire utilisent l'acier HDG et Al-Zn-Mg. Ceux-ci allient la résistance à la protection contre la rouille. Cela assure la durabilité dans les conditions météorologiques difficiles. Il prolonge la durée de vie des installations extérieures.

Conçu pour résister aux typhons, aux tremblements de terre et aux fortes charges de neige

Le système de suivi CZT Four Directions améliore l'efficacité des panneaux solaires. Il se déplace dans quatre directions. Il est construit pour résister aux tremblements de terre et aux vents typhons. Cette conception maintient les panneaux alignés. Il maintient les supports forts dans des conditions extrêmes.

Installation facile avec conception modulaire réduisant le travail sur place

CZT’ Les modules préfabriqués simplifient la mise en place. Ils réduisent le temps de travail et les coûts. Cela améliore la sécurité sur les sites difficiles. Les montagnes ou les plaines inondables en sont des exemples. La conception modulaire assure un assemblage rapide et solide.

Fonctions de drainage et de ventilation intégrées pour prévenir la corrosion

CZT’ les supports comprennent des canaux de drainage. Ceux-ci arrêtent l'accumulation d'eau. Les espaces de ventilation permettent le flux d'air. Cela réduit l'humidité après les tempêtes ou les inondations. Ces caractéristiques renforcent la résistance à la rouille. Ils prolongent la vie du système.

En confiance des constructeurs dans les zones côtières et sismiques

CZT’ ses solutions sont utilisées dans des milliers de projets dans le monde entier. Ceux-ci comprennent les champs de montagne et les fermes côtières. Son accent sur l'ingénierie métallurgique avancée en fait un leader. Il excelle dans l'infrastructure résistante aux catastrophes.

FAQ

Q: Pourquoi l'acier inoxydable est-il préféré à l'acier au carbone ordinaire dans les bâtiments résistants aux catastrophes?

R: L'acier inoxydable résiste mieux à la rouille. Il se plie davantage sous stress, comme dans les tremblements de terre ou les ouragans. Il est également résistant à la chaleur élevée, contrairement à l'acier au carbone.

Q: L'acier inoxydable peut-il être utilisé efficacement à l'extérieur près des océans?

R : Oui. Sa teneur en chrome forme un bouclier contre la rouille liée au sel. C'est bon pour les zones côtières.

Q: L'utilisation d'acier inoxydable augmente-t-elle considérablement les coûts globaux de construction?

R : Les coûts initiaux peuvent être plus élevés. Acier inoxydable’ La longue durée de vie réduit les besoins de réparation et de remplacement. Cela permet d’économiser de l’argent dans des conditions difficiles.

Q: Y a-t-il différents types de formes en acier inoxydable disponibles en fonction de l'application?

R : Oui. Des formes telles que les canaux en C, les poutres en Z et les canaux unistrut sont prises pour des besoins spécifiques. Ceux-ci comprennent la manipulation des forces latérales ou verticales.

Q: Comment fonctionne l'acier inoxydable structurellement après l'exposition aux eaux d'inondation?

R: L'acier inoxydable conserve sa forme et sa résistance après une longue exposition à l'eau. Sa résistance à la rouille assure une fiabilité dans les zones sujettes aux inondations.