Picking the right building material sets the durability, cost savings, and safety for any engineering job. Both methods use the same starting material. Yet, cold-rolled steel shapes and hot-rolled steel vary a lot in strength traits, size accuracy, and surface look. For fields needing exact work, like solar frames and current buildings, knowing these points is key to better supply choices and structural strength.

Fundamental Differences Between Hot and Cold Rolling Processes

The Basics of Hot Rolled Steel Manufacturing

Hot-rolled steel making starts at very high heat, often over 1,700°F. This level goes past the metal’s remake point. Such heat makes the steel simple to shape into big forms, like thick I-beams and track rails. But as it cools, the steel pulls in a bit. This means less grip on the end size and form. So, hot-rolled steel fits uses where exact measures matter less. Think railroad paths or solid building bases.

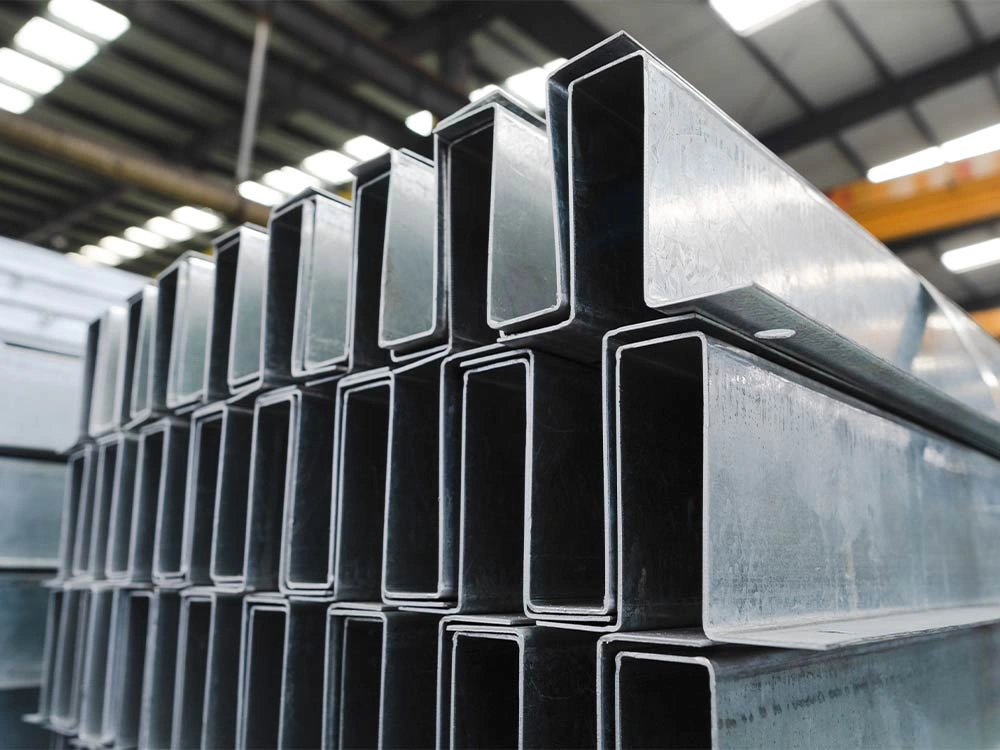

How Cold Rolled Steel Shapes Are Processed

Cold-rolled steel shapes get extra work at normal room temperature. This brings better size accuracy and surface evenness. The steps include cooling the hot-rolled steel first. Then, it gets rolled or shaped again at room temperature to meet clear specs. This room-heat shaping makes the metal tighter in measures and straighter in lines. A good case is the Viga de acero Omega. It uses a special closed shape for better twist resistance and weight hold. Such detail is hard to get with the usual hot rolling.

Comparison of Physical Properties and Surface Finish

Dimensional Tolerance and Precision Levels

Exact building work counts on close size limits that only cold rolling and cold shaping can give. The material forms at room temperature. So, it skips the pull-in and bend from hot rolled cooling. This evenness matters for parts like the Canal de acero C (C-Purlin). It needs to join smoothly with other building parts in the setup. The steady sizes of cold-shaped C-channels let pre-cut holes line up right. This cuts work time and setup effort on-site.

Surface Quality and Aesthetic Appeal

Surface finish acts as a critical differentiator, with cold-rolled steel offering a smooth, scale-free texture ideal for coating and painting. Hot-rolled steel naturally forms a rough, blue-grey oxide scale on its surface as it cools, which requires abrasive blasting to remove before any finishing can occur. Cold-rolled shapes, however, present a polished surface that readily accepts galvanizing or powder coating. This is particularly important for exposed architectural elements or solar structures where visual uniformity and immediate corrosion protection are required.

Strength and Hardness Characteristics

Cold shaping boosts the yield strength and toughness a lot. It does this via a method called strain hardening. The steel gets pressed and formed at room temperature. Its inner crystal setup changes. This makes the end item tougher and stronger than hot-rolled ones. The better strength per weight lets builders pick slimmer, lighter forms. They keep the same weight hold.

Diverse Applications of Cold-Rolled Steel Shapes in Industry

Structural Components for Solar Energy Systems

The solar industry exclusively utilizes cold-formed steel profiles to ensure structural integrity against wind and snow loads while minimizing dead weight on roofs or land. High-performance mountings must endure harsh environments for decades. The Canal de acero Z is a preferred solution in this sector; its unique geometry allows for overlapping (nesting) at supports, which effectively doubles the strength at critical stress points. This makes Z-channels ideal for solar racking purlins where maximizing span distance and load capacity is essential.

C-Channels and Z-Channels in Modern Construction

Current pre-made buildings rely on flexible forms like C-channels and Z-channels. They aid fast wall and roof framing. Unlike thick hot-rolled beams, these light cold-shaped items handle easily. Transport is simple too. They see wide use in factory buildings, storage spots, and mid floors. Speed in putting together is the main goal.

Automotive and OEM Manufacturing Parts

Makers need the close limits of cold-rolled steel for pressed car parts and machine bits. The steady material makes sure each pressed item matches. This is a must for big run lines and OEM cut parts.

Cost Analysis: Is Cold Rolled Steel Worth the Investment?

Initial Material Costs vs. Processing Expenses

The starting buy price of cold-rolled steel runs higher. This comes from added process steps. But the full own cost often ends lower for exact jobs. Hot-rolled steel needs extra cutting, grinding, or fixing to hit specs. That adds work costs. Cold-rolled shapes come set to use. This smooths the making process.

Savings Through Reduced Material Weight and Waste

Utilizing high-strength cold-formed shapes allows engineers to reduce total steel tonnage without compromising structural safety. Because cold working increases yield strength, a thinner gauge of cold-rolled steel can often replace a thicker, heavier hot-rolled section. This reduction in weight directly translates to lower shipping costs and lighter foundation requirements.

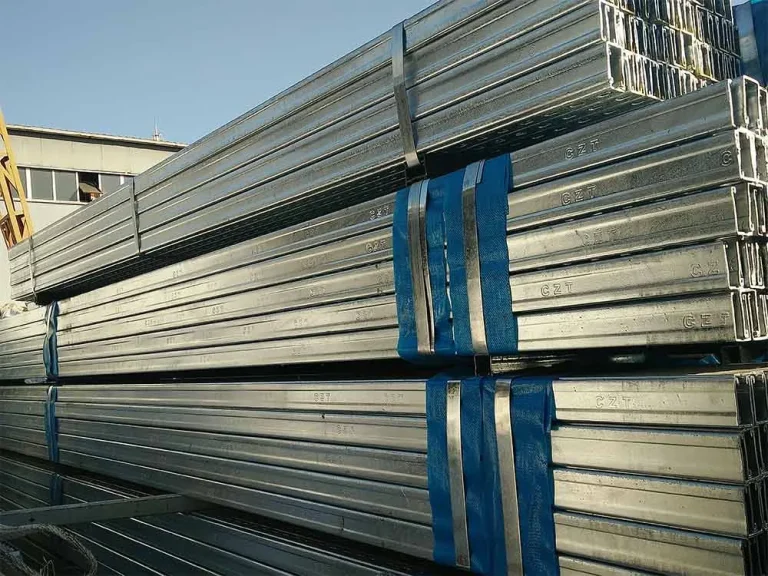

Why Choose CZT Solar for High-Performance Cold-Formed Steel?

Expertise in Producing C, Z, and Omega Steel Channels

We use modern cold shaping tech to make close-tolerance building forms. They meet strict world standards. At CZT solar, our cold-formed steel shop has 25 cold-forming lines and 15 punching lines. This setup lets us make many shapes. Think Unistrut, C types, Z Types, and Omega Types. Monthly output hits 5,000 tons. Our adherence to the 6S management system ensures each form leaves with the right size specs.

Customized Solutions for Global Photovoltaic Projects

Our build team gives full solar power station fixes. They fit to set land and weather spots. If your job needs a C Steel Channel for roof setups or a solid Z Steel Channel for big projects, we do full custom. Pick thickness, length, and steel type like Q235 or Q345. We blend R&D, making, and sales. This brings holds that match your special job needs. From factory zones to hard hill setups.

Advanced Surface Treatments and Durability

We make sure long rust fight with top surface fixes. These include Pre-galvanizing, Hot-Dip Galvanizing (HDG), and new Zn-Al-Mg steel coats. Solar jobs require over 25 years of work. Our items come with a 15-year warranty. Our tight check rules cover size, looks, and ISO and SGS standards. They make sure our steel forms take the toughest weather hits.

Preguntas frecuentes

Q: What is the primary benefit of using cold-formed steel for solar mounting?

A: The primary benefit is the superior strength-to-weight ratio. Cold-formed steel, like high-grade C and Z channels, provides the necessary structural rigidity to withstand wind and snow loads while being lightweight enough to reduce transportation costs and simplify installation on rooftops or ground terrains.

Q: How does cold-rolled steel compare to hot-rolled steel in terms of surface finish?

A: Cold-rolled steel has a much smoother, cleaner surface compared to the rough, scaly finish of hot-rolled steel. This makes cold-rolled options far better suited for projects requiring aesthetic appeal or immediate application of protective coatings like galvanization or paint without extensive surface preparation.

Q: Can cold-rolled steel shapes be customized for specific construction designs?

A: Yes, cold-rolled steel is highly customizable. Because the process is performed at room temperature with precision machinery, manufacturers can easily cut, punch, and form the steel into specific lengths, thicknesses, and complex cross-sections (like Omega or Z shapes) to meet exact architectural or engineering blueprints.

Q: Which steel grade is best for high-corrosion environments?

A: For high-corrosion environments, cold-rolled steel treated with Hot-Dip Galvanizing (HDG) or Zinc-Aluminum-Magnesium (Zn-Al-Mg) coatings is recommended. These treatments provide a self-healing barrier against rust and oxidation, significantly extending the service life of the structure in coastal or industrial areas.

Q: What are the top companies for industrial photovoltaic support structures?

A: Top companies are those that offer integrated R&D and manufacturing capabilities with international certifications. Look for manufacturers like CZT solar that provide a one-stop service, possess extensive cold-forming production lines, and offer comprehensive warranties (e.g., 15 years) to ensure project longevity and reliability.