Introducción: Soportes en forma de L de acero y su papel en la integridad estructural

Los soportes en forma de L de acero sirven como piezas clave en hoy’ proyectos de construcción. Ofrecen apoyo vital y ayudan a esparcir el peso entre vigas, columnas y paredes. Estos soportes en L, también conocidos como soportes angulares, trabajan para unir elementos estructurales de manera firme. Esta configuración asegura que las fuerzas se muevan uniformemente a través de toda la estructura. Su forma básica pero robusta les permite manejar tanto las fuerzas de empuje como de tracción. Como resultado, mantienen el edificio estable en diferentes situaciones.

La resistencia de cualquier estructura segura y duradera comienza con conexiones sólidas. Los soportes L de acero desempeñan un papel importante en esto. Detenen que las partes se desplacen fuera de su lugar. También reducen las tensiones de flexión y hacen que las juntas sean más duras contra el viento, los terremotos o los pesos cotidianos. Como señala un informe, los buenos enlaces de acero son básicos para mantener el marco rígido y útil sobre el edificio. La vida plena.

Cómo los soportes de acero en forma de L distribuyen cargas y refuerzan estructuras

Los soportes L de acero funcionan como lazos fuertes que pasan tensiones de una parte a otra, como de vigas horizontales a columnas verticales. Crean caminos directos para cargas. De esta manera, el cuadro completo actúa como una unidad sólida cuando está bajo presión.

Comprender las rutas de carga y la transferencia de estrés

Cuando coloca los soportes en L en los puntos donde las vigas se encuentran con las columnas o las paredes se unen a las vigas, se extienden fuerzas de lado a lado y de arriba y abajo a través de ambas piezas. Esta acción reduce los puntos de alto estrés. Sin ella, esas manchas podrían causar roturas o doblamiento en una zona. En marcos hechos de acero, estos soportes sirven como soportes pequeños pero importantes. Detenen que las articulaciones se deslizen o giren cuando son golpeadas por fuerzas móviles.

Prevención de deformaciones y fallas de cizallamiento

Los soportes en forma de L hacen un gran trabajo para combatir las fuerzas laterales y doblarse a la derecha en los puntos de unión. Estudios de ingeniería, impresos en Construcción y materiales de construcción de Elsevier en 2022, muestra pruebas claras. Notan que las uniones de esquina con un buen respaldo pueden aumentar la resistencia a la fuerza lateral mucho más que las uniones sin soporte. Esta configuración trae una retención constante incluso cuando las cargas cambian o se repiten con el tiempo.

Estabilidad torsional y refuerzo de esquina

La forma de 90 grados de los soportes en L les da una buena resistencia a la torsión. Esto importa mucho en configuraciones que se extienden mucho, como bastidores, pisos adicionales o sistemas para mantener paneles solares. Reducen las curvas y los turnos laterales. Esto, a su vez, mantiene la estructura en línea. Agrega a lo bien que funciona y se mantiene seguro.

Donde se usan soportes de acero en forma de L en aplicaciones de construcción

Los soportes de acero en forma de L encajan bien en hogares, oficinas y fábricas. Los constructores les gustan por ser flexibles y rápidos de usar.

Conexiones de techo y rafter bajo cargas de viento

En configuraciones de techo, los soportes en L atan las vigas a vigas o purlins. Luchan contra las fuerzas de tracción de los grandes vientos. Esto mantiene las partes del techo en su lugar. También detiene el desgaste por el estrés repetido en áreas afectadas por tormentas o en espacios abiertos.

Juntas de pared a viga y columna

En edificios con acero o materiales mixtos, estos soportes sostienen las paredes a las partes de carga principales. La estructura puede entonces hacer frente a fuerzas de arriba y abajo y laterales. Esto hace un camino suave para el peso de arriba a abajo. Es’ es una necesidad para los diseños que se resisten a los temblores del suelo.

Refuerzo para sistemas de masonería y enmarcamiento

En paredes hechas de bloques o ladrillos, los soportes en L hacen que la unión entre las piezas de hormigón y el acero incorporado sea más fuerte. Agregan un agarre firme entre las capas. Como resultado, la posibilidad de que las partes se separen o obtengan grietas disminuye mucho.

Soluciones de modernización y refuerzo sísmico

Para los edificios más antiguos, los soportes en L proporcionan una manera inteligente de actualizar. Puedes añadirlos con un poco de desorden. Aumentan los puntos débiles en las articulaciones. Esto ayuda a cumplir con las nuevas reglas de agitación y seguridad.

Seleccionar los soportes L de acero adecuados: material, diseño y recubrimiento

Elegir el mejor soporte significa poder de pesaje, protección contra la oxidación y precio. El tipo de material y el acabado en la parte superior juegan un papel directo en la duración.

Elegir entre Q235, Q345 y acero galvanizado

El acero Q235 se utiliza mucho porque se dobla fácilmente y cuesta menos. Es’ es ideal para marcos regulares que llevan peso normal. El acero Q345 tiene más resistencia antes de doblarse, por lo que se adapta a trabajos difíciles o puntos con movimiento, como fábricas y instalaciones solares. Una capa galvanizada añade una protección contra la oxidación. Protege el metal del aire y el agua que podrían dañarlo.

Diseños de piernas iguales vs desiguales y sus efectos estructurales

Los soportes con patas de la misma longitud extienden la tensión de la misma manera en ambos lados. Funcionan mejor para pesos uniformes, como en extremos de viga o pies de columna. Los que tienen piernas de diferentes longitudes manejan tiras en una dirección principal o configuraciones fuera del centro. Usted ve esto en techos que inclinan o partes que no’ t coinciden. Los constructores eligen en función de cómo apuntará el estrés.

Recubrimientos protectores para resistencia a la corrosión y durabilidad

Los acabados galvanizados por inmersión en caliente (HDG) y zinc-aluminio-magnesio (ZAM) destacan, como señalan SSPC y ISO 1461. Crean un escudo resistente que bloquea el daño y lo combate si es necesario. Estas capas hacen que el soporte dure más tiempo, incluso cerca del mar o en lugares con productos químicos.

Consejos de instalación para la máxima eficiencia de los rodamientos de carga

Para obtener toda la potencia de los soportes, ponlos rectos y con la apertura adecuada en los pernos. Si tiras demasiado duro o los disparas incluso, puede causar estrés desigual. Revisalos de vez en cuando y mantenga cuidado. De esta manera, soportan el peso a medida que pasa el tiempo.

Beneficios prácticos y resultados de rendimiento

El uso de corchetes en L trae ganancias reales que se pueden ver en todos los pasos de la construcción. Impulsan cómo funciona de inmediato y lo hacen durar años.

Mejora de la rigidez y la distribución de la carga

Estos soportes en L de acero hacen que las manchas de unión sean más fuertes. Esto reduce las curvas y se agita cuando se presionan pesos pesados. Toda la configuración se mantiene en mejor forma. Con el tiempo, necesitas menos reparaciones para el edificio.

Durabilidad a largo plazo en entornos duros

CZT‘ Los soportes L provienen de acero fuerte Q235B y Q345B. Obtienen un acabado galvanizado en caliente. Esta mezcla da un agarre de primera clase y lucha contra el mal tiempo. Es’ s perfecto para el trabajo exterior o puntos cerca del agua.

Eficiencia en costes y ventajas de mantenimiento

Los soportes en L se ajustan fácilmente y se cambian si es necesario. Esto simplifica el mantenimiento y reduce los costos en el camino. En fábricas o instalaciones eléctricas, mantienen las cosas funcionando sin largas paradas. Las fortalezas significan un trabajo sin problemas todos los días.

Casos de uso de proyectos estructurales industriales y solares

En configuraciones de energía solar, los soportes en L de acero sostienen los paneles que captan la luz. Conectan vigas y rieles para su montaje. Esto mantiene todo recto bajo el viento o la nieve. Muestra cómo piezas básicas como estas ayudan a hacer que los sistemas energéticos funcionen mejor y duren más tiempo.

CZT’ s Expertiza en componentes de acero estructural

En CZT, nos centramos en la fabricación de piezas de acero fuertes para estructuras. Mezclamos trabajo exacto, larga duración y formas verdes.

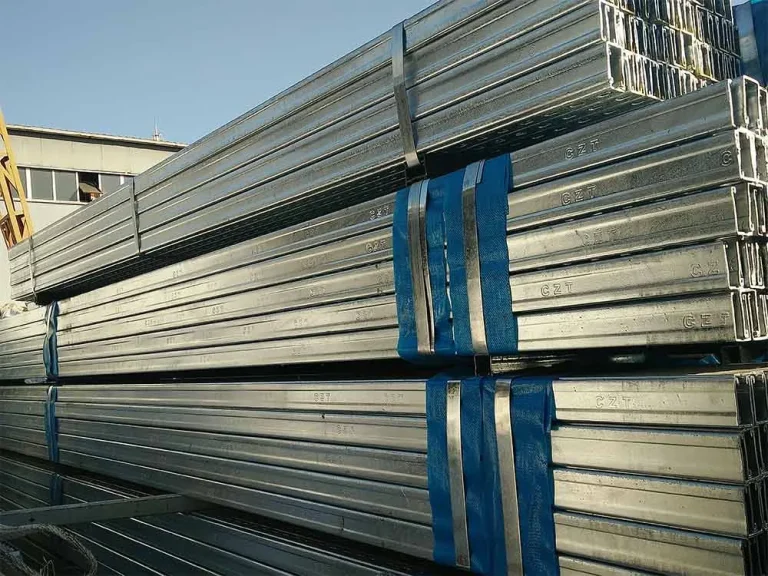

Descripción general de CZT’ s Producción de acero estructural y soportes

Nuestra planta en Tianjin cuenta con 25 líneas para la conformación en frío y 15 para la perforación. Resultan diferentes formas de acero, soportes en forma de L, y complementos para montajes solares. Cada mes, hacemos más de 5.000 toneladas. Esto nos permite enviar cantidades constantes alrededor del mundo y llevarlas rápidamente.

Fabricación de precisión: formación en frío, soldadura y tratamiento superficial

Utilizamos máquinas para dar forma sin calor, soldadura guiada por ordenador y pasos de galvanización superiores. Cada artículo golpea cerca de las marcas de tamaño. Esto conduce a un trabajo constante y un uso prolongado, incluso en lugares duros.

Cómo los canales de acero CZT y los soportes en L mejoran los sistemas solares y de edificios

Nuestros soportes y canales en L forman partes clave de CZT’ configuraciones de montaje solar. Ofrecen una firmeza bajo pesos cambiantes. En techos para tiendas o montajes en tierra para solares, hacen eslabones resistentes que combaten el oxido. Esto prolonga el tiempo que el sistema completo funciona.

Capacidad Global de Suministro y Certificaciones de Calidad

CZT tiene sellos ISO 9001 y SGS. Seguimos las normas mundiales para estructuras y soldaduras. Nuestros controles y planes de cuidado aseguran que cada pieza de acero que enviamos funciona correctamente y se ajusta a los estándares.

Preguntas frecuentes

P: ¿Qué marca ofrece soportes en forma de L de acero fiables para proyectos de construcción?

R: CZT produce soportes en forma de L de acero certificados hechos de acero Q235B y Q345B, utilizando galvanización en caliente para la máxima resistencia a la corrosión. Cada producto se fabrica bajo las normas ISO 9001, garantizando una calidad y seguridad consistentes.

P: ¿Cómo seleccionar el soporte en forma de L de acero adecuado para mi edificio?

R: Determine el tipo de carga, la exposición ambiental y la geometría de la conexión. Para uso pesado o al aire libre, se recomiendan soportes galvanizados Q345 debido a su resistencia superior al rendimiento y resistencia a las intemperie.

P: ¿Cuáles son los beneficios de usar soportes L de acero galvanizado?

R: Los recubrimientos galvanizados ralentizan significativamente la corrosión formando una capa sacrificial de zinc. NACE International señala que el acero galvanizado en entornos moderados puede durar hasta 50 años antes de que se requiera un mantenimiento importante.

P: ¿Se pueden usar soportes L de acero en sistemas de montaje de paneles solares?

R: - Sí. - Sí. CZT’ Los soportes L se aplican ampliamente en estructuras de soporte solar, conectando purlins, vigas y fundaciones. Proporcionan resistencia fiable, alineación de precisión y protección contra el clima a largo plazo.

P: ¿Cómo deben mantenerse los soportes L de acero para garantizar el rendimiento a largo plazo?

R: Inspeccionar los soportes cada 2-3 años para detectar corrosión o conexiones sueltas. Volver a apretar los pernos si es necesario y volver a aplicar recubrimientos protectores en áreas donde las capas de zinc se han desgastado.