Formas de acero en sistemas de montaje solar: por qué los perfiles de acero importan en 2025

Formas de acero como base estructural de sistemas de montaje fotovoltaico

Cómo las formas de acero determinan el soporte de carga y la estabilidad estructural

Las formas de acero definen la capacidad de carga y la seguridad estructural de los sistemas de montaje solar porque la geometría de cada perfil influye en cómo se transfieren y absorben las fuerzas. A medida que los módulos crecen y los requisitos de viento y nieve aumentan, las formas de acero deben garantizar la rigidez bajo tensión mecánica. Las vigas, canales o pilas tubulares adecuadamente seleccionados evitan la deformación y aseguran los conjuntos fotovoltaicos en diversos entornos de instalación.

Por qué los perfiles de acero siguen siendo dominantes sobre el aluminio en proyectos fotovoltaicos

Las formas de acero se mantienen por delante del aluminio. Lo hacen con mayor firmeza, mayor sujeción al desgaste y una mejor acción en amplios alcances. El aluminio reduce el peso, claro. Sin embargo, el acero trae la calidad duradera que la gran potencia y los trabajos de fábrica exigen. El acero encaja bien con la formación en frío, la formación en rollos y la soldadura, también. Eso abre más opciones de construcción que las configuraciones de aluminio proporcionan.

Composición del material e impacto del recubrimiento en las formas del acero

Influencia del acero Q235/Q355, HDG y Zn-Al-Mg en la vida útil del sistema

Los grados de acero como Q235B y Q355B aumentan mucho la vida útil de las formas en construcciones solares. Mezclarlos con revestimientos HDG o Zn-Al-Mg, y se resisten al oxido en condiciones climáticas difíciles. Los recubrimientos de Zn-Al-Mg proporcionan una protección de borde sólida para piezas delgadas en forma de rodillo. Esto los convierte en una opción preferida para purlins solares y rieles que se ocupan del contacto continuo al aire libre.

Resistencia ambiental requerida para 25 años de operación al aire libre

La resistencia ambiental es esencial porque las estructuras fotovoltaicas deben funcionar durante más de dos décadas bajo UV, humedad y variaciones de temperatura. Las formas de acero emparejadas con recubrimientos adecuados evitan la oxidación y el debilitamiento del material. En zonas costeras o agrícolas, la protección contra la corrosión mejorada garantiza una resistencia estructural consistente en todo el sistema. vida útil.

Formas comunes de acero usadas en sistemas de montaje solar

Secciones estructurales huecas y acero tubular para PV de montaje en tierra

Tubos redondos, cuadrados y rectangulares en fundaciones solares

Los tubos HSS distribuyen las fuerzas de compresión de manera eficiente y resisten la torsión, lo que los convierte en componentes esenciales de la base. Los tubos redondos, cuadrados y rectangulares proporcionan soporte estable en sistemas de inclinación fija y seguimiento, ofreciendo un equilibrio entre la capacidad de carga y la eficiencia del material.

Fundaciones de pilas y pilas de tornillo para sitios de montaña y costeros

Los cimientos de pilas y pilas de tornillo permiten una fijación rápida y profunda en el suelo con terreno áspero. El Fundación de pila tipo H para sistema de montaje solar en tierra da una fuerte sujeción de arriba hacia abajo y empuje lateral hacia atrás. Se adapta bien a grandes configuraciones de energía. Tornilla pilas de tierra rocosa o inclinada. Además, siguen cavando al mínimo.

C-Steel, Z-Steel y U-Channels como formas centrales de acero en marcos fotovoltaicos

Aplicaciones C-Channel en Bracing, Purlins y Module Rails

Los canales C se clasifican como una de las formas de acero habituales para construcciones fotovoltaicas. Ofrecen firmeza y ajuste sencillo. El Canal de acero C trae forma exacta, configuración rápida y buena flexión. Así que funciona para purlins, refuerzos y rieles de módulos. Esto se aplica tanto a los sistemas de montaje en techo como en tierra.

Aplicaciones de canal Z en estructuras de techo ligeras

Los canales de acero Z ligeros y fuertes ofrecen una impresionante capacidad de anidación. Su forma mejora la rigidez en flexión y proporciona un rendimiento ideal en aplicaciones de techos de larga extensión, como techos metálicos comerciales, donde la distribución del peso es un problema crítico.

Formas pesadas de acero: vigas H, vigas I y vigas Ω

Vigas H para columnas de carport y áreas de carga de viento/nieve

Las vigas H proporcionan energía de primera clase para carports y construcciones de cubiertas. Allí, toman pesos fotovoltaicos y presiones meteorológicas. Sus lados iguales se extienden bien. Esto respalda grandes extensiones y zonas con pesada acumulación de nieve.

Vigas Omega e I para marcos fotovoltaicos industriales, curvos y de largo alcance

Las vigas Omega y I aportan una fina firmeza de torsión. Se ajustan a construcciones solares anchas y dobladas. Su forma corta la caída. También garantiza una acción constante en los trabajos de fábrica que requieren una fuerte firmeza.

Perfiles laminados y canales Unistrut en sistemas fotovoltaicos modulares

Perfiles de acero laminados para instalaciones eficientes en techos

Los perfiles formados en rollos dan una forma ligera y constante. Aceleran el ajuste en C& Los techos. Agujeros hechos por adelante y cuidadoso moldeo, recorte tiempo de trabajo. Aumentan el revestimiento del panel también en grandes configuraciones empresariales.

Canales Unistrut para montaje fotovoltaico industrial rápido

Los canales Unistrut ofrecen cambios fáciles y ajuste rápido. Se adaptan bien a los bastidores del inversor, los caminos de cable y las construcciones laterales. Sus ranuras abiertas ayudan a configuraciones dobladas sin perforación.

Compatibilidad de formas de acero con diferentes tipos de sistemas de montaje solar

Formas de acero para estructuras solares montadas en tierra

Pilos tubulares y pilas H para granjas solares a escala de servicios públicos

Las granjas montadas en tierra cuentan con bases tubulares y en pila H para enfrentar cargas laterales y de tracción. Estas formas mantienen las cosas estables en tierra abierta. El viento golpea fuerte allí. La profundidad del suelo también cambia a menudo.

Acero Zn-Al-Mg para entornos duros y regiones corrosivas

Las formas de acero recubiertas con Zn-Al-Mg se adaptan a manchas con alto riesgo de oxidación. Tienen revestimiento de zinc regular. Su guardia tiene un valor real en lugares solares costeros y agrícolas.

Formas de acero para estructuras solares montadas en tierra

Pilos tubulares y pilas H para granjas solares a escala de servicios públicos

Las granjas montadas en tierra dependen de fundaciones tubulares y de pilas en H para soportar cargas de elevación y laterales. Estos perfiles garantizan la estabilidad en campos abiertos donde la exposición al viento es alta y la profundidad del suelo varía.

Acero Zn-Al-Mg para entornos duros y regiones corrosivas

Las formas de acero recubiertas con Zn-Al-Mg son ideales en entornos resistentes a la corrosión, superando el rendimiento de la galvanización estándar. Su protección es especialmente valiosa en sitios solares costeros y agrícolas.

Formas de acero para sistemas solares en techos

Secciones C y rieles para techo metálico y C& I Edificios

Las secciones cesarias y los carriles proporcionan un soporte fuerte pero de bajo peso para los módulos de techo. Su geometría funciona bien con abrazaderas de techo y minimiza la carga puntual en techos metálicos.

Perfiles Unistrut para diseños de techo balastado y plano

Los perfiles Unistrut mejoran la flexibilidad en los sistemas de techo plano, lo que permite a los instaladores ajustar los ángulos de inclinación y colocar el lastre con precisión.

Formas de acero para alfombras solares y estructuras de dosel

Columnas H-Beam para soporte de carga fotovoltaica para vehículos

Los carports requieren formas de acero que manejen cargas combinadas fotovoltaicas y de vehículos. Las columnas de viga en H proporcionan la rigidez necesaria para estacionamientos comerciales de gran envergadura y estructuras de carga de vehículos eléctricos.

Vigas C/Z para soporte de techo y diseño de drenaje integrado

Las vigas C y Z soportan las purlinas del techo e integran canales de drenaje, lo que permite el encaminamiento limpio del cable y la impermeabilización.

Formas de acero para la energía fotovoltaica flexible en montañas, lagos y agricultura

Sistemas de cables prestresos de columnas de acero para terrenos desiguales

Las aplicaciones de montaje flexibles se benefician de columnas de acero emparejadas con cables tensados. El sistema de montaje solar flexible aplica este principio para recorrer grandes distancias a través de paisajes desiguales.

Apoyo de acero a largo plazo para proyectos fotovoltaicos de pesca, tierras agrícolas y lagos

Los sistemas de acero de largo alcance permiten el despliegue fotovoltaico sobre cuerpos de agua o tierras agrícolas, mejorando la eficiencia del uso de la tierra al tiempo que proporcionan un alto espacio libre estructural.

Calidad, procesamiento y recubrimiento: garantizar que las formas de acero funcionen más allá de las expectativas

Tratamientos anticorrosivos para formas de acero de larga duración

HDG vs Pregalvanizado vs Zn-Al-Mg para diferentes condiciones climáticas

El HDG se adapta a vigas gruesas en entornos duros, las obras de acero pre-galvanizado para climas suaves y el Zn-Al-Mg sobresale en regiones corrosivas que requieren protección a largo plazo.

Selección de recubrimientos para regiones con alta humedad, pulverización de sal y frío

La selección adecuada del recubrimiento asegura que las formas de acero mantengan el rendimiento estructural bajo condiciones de humedad, sal o congelación.

Tecnología de procesamiento detrás de formas de acero de alta precisión

Formado en frío, perforación y corte láser para estructuras fotovoltaicas

La formación en frío y el corte láser proporcionan una alta precisión y consistencia, lo que apoya la producción en masa eficiente de componentes fotovoltaicos.

Soldadura, flexión y pre-montaje para mejorar la eficiencia en el sitio

Los componentes preassemblados y las estructuras soldadas reducen el tiempo de instalación, especialmente en proyectos a escala de servicios públicos.

Cómo las formas de acero influyen en el ROI del proyecto, el costo y el rendimiento técnico

Optimización de las formas de acero para la rentabilidad del proyecto

Diferencias de costos entre secciones pesadas y formas en rollo

Las formas formadas en rollos ofrecen soluciones rentables para techos, mientras que las vigas pesadas soportan tramos más largos con menos riesgos estructurales.

Cómo la selección correcta de la forma de acero reduce la sobreingeniería

El uso de la forma correcta de acero evita el refuerzo innecesario, reduciendo los costos de material y mano de obra mientras se mantiene la seguridad.

Factores de vida útil, garantía y mantenimiento de las formas de acero

Rendimiento estructural durante más de 25 años en condiciones difíciles

Con la forma y el recubrimiento adecuados, las estructuras de acero soportan de manera fiable las fluctuaciones del viento, la nieve y la temperatura durante décadas.

Reducir el mantenimiento a través de opciones de forma de acero más inteligentes

Mejores opciones de geometría y recubrimiento reducen la frecuencia de inspección y los costos de mantenimiento a largo plazo.

CZT Solar — Un proveedor líder de formas de acero para sistemas de montaje fotovoltaico

Formas completas de la cartera de acero para todas las aplicaciones fotovoltaicas

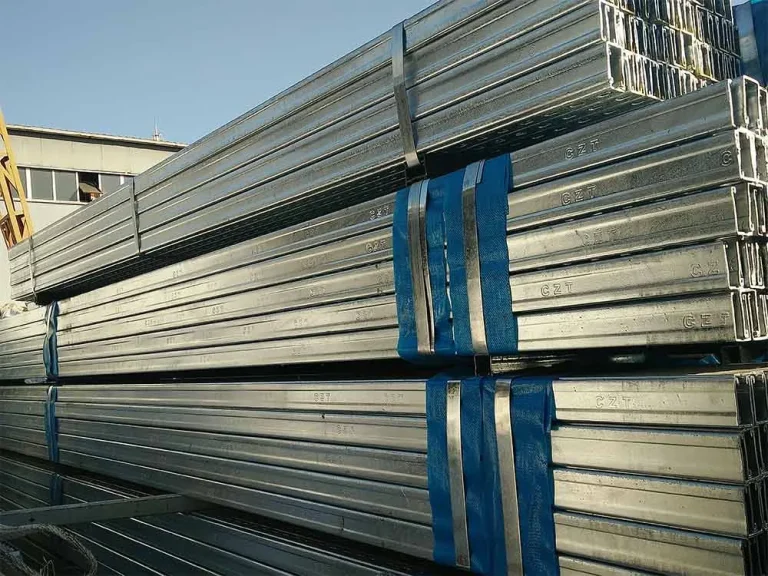

Vigas C/Z/U/Ω/H, pilas de tuberías, pilas de tornillo y perfiles personalizados

En CZT solar, ofrecemos perfiles C / Z / U, vigas Omega, vigas H, pilas de tuberías, pilas de tornillos y soluciones de acero formado en rollos personalizadas para suelo, techo, carport y sistemas fotovoltaicos flexibles.

Sistemas de montaje flexibles para montañas, lagos y tierras agrícolas

Nuestras estructuras de montaje flexibles soportan el despliegue fotovoltaico en terrenos desiguales, superficies de agua y tierras agrícolas.

Fuertes capacidades de fabricación detrás de las formas de acero solar CZT

25 Líneas de formación en frío, corte láser, soldadura y fabricación OEM

Operamos 25 líneas de formación en frío, sistemas de corte láser, estaciones de soldadura e instalaciones OEM para entregar productos de acero de alta precisión.

28,000㎡ Producción Anual de Estructura de Montaje de Fábrica 10GW

Nuestros 28.000 ㎡ La fábrica produce hasta 10GW de estructuras de montaje anualmente, asegurando un suministro estable para proyectos globales.

Apoyo de ingeniería global y experiencia probada en proyectos

Soluciones para montaje en tierra, Carport, C& I Estructuras de techo y BIPV

Ofrecemos soluciones de ingeniería que cubren aplicaciones de montaje en tierra, techo, carport y aplicaciones fotovoltaicas flexibles en diversos climas.

Dibujos de ingeniería personalizados, cálculos de carga y pre-montaje

Nuestros servicios incluyen cálculos estructurales, dibujos de ingeniería y soporte pre-montaje para agilizar la instalación.

Preguntas frecuentes

P: ¿Qué formas de acero son más fiables para sistemas de montaje solar?

R: Formas como canales C, vigas Z, vigas H, pilas tubulares y vigas Ω ofrecen un rendimiento probado en diversas aplicaciones fotovoltaicas.

P: ¿Cómo afectan los tipos de revestimiento a la durabilidad de las formas de acero?

R: Los recubrimientos como HDG y Zn-Al-Mg mejoran significativamente la resistencia a la corrosión, especialmente en entornos costeros o agrícolas.

P: ¿Qué formas de acero funcionan mejor para el techo solar?

R: Los perfiles ligeros como las secciones cesarias, los rieles y los canales Unistrut proporcionan suficiente resistencia con una carga mínima en el techo.

P: ¿Cómo afectan las condiciones del suelo a la selección de la forma de acero?

R: La dureza del suelo, la exposición al viento y el terreno determinan si los pilares tubulares, los pilares H o los pilares de tornillo son los más adecuados.

P: ¿Qué marca suministra formas de acero de alta calidad para el montaje fotovoltaico?

R: CZT solar ofrece una cartera completa de formas de acero, incluyendo perfiles C / Z / U, vigas H, pilas tubulares y sistemas de montaje flexibles.