ما الذي يجعل نسبة القوة العالية إلى الوزن من H Shape Steel قيمة جداً؟

كيف H Shape Steel يحسن أداء الحمل

فولاذ على شكل H، المعروفة أيضًا باسم شعاع H أو شعاع الواجهة الواسعة ، لها شكل خاص يجعلها رائعة لعمل الأشياء الثقيلة. جوانبها المسطحة والجزء الوسطى المستقيم يساعدها على مكافحة الانحناء والالتواء. هذا الإعداد يضع المواد حيث’ احتاج أكثر ، والحفاظ على ضوء شعاع ولكن قوي. لذلك ، يمكن للفولاذ على شكل H حمل حمولات كبيرة على امتدادات طويلة دون الانحناء أو التقطيع.

لماذا الكفاءة الهيكلية مهمة في البناء الحديث

في اليوم’ عمل البناء ، تعني الكفاءة القيام بالكثير مع القليل. H على شكل الصلب’ نسبة القوة إلى الوزن العالية تسمح للمبنين باستخدام إطارات أخف وزنا تبقى قوية. هذا يأخذ الضغط على الأساس، ويجعل الشحن أسهل، ويسرع العمل. بالنسبة للمباني الطويلة أو الجسور أو المصانع ، يعني هذا المزيد من المساحة المفتوحة والأشياء الأقل هدراً.

مقارنة مقاييس القوة للصلب على شكل H بالمواد الهيكلية الأخرى

مقارنة بالخشب أو الخرسانة ، فإن الصلب على شكل H أقوى بكثير لكل من قوى السحب والدفع. الخشب هو جيد للوظائف الصغيرة ولكن هو’ t ثابت أو آمن للحريق مثل الصلب. مقبضات الخرسانة تدفع بشكل جيد ولكن تحتاج إلى مساعدة إضافية للسحب. الفولاذ على شكل H يفعل كلاهما في قطعة واحدة ، مما يجعله مثاليًا للظروف القاسية مثل الرياح أو الزلازل.

كيف تعزز مرونة تصميم الصلب على شكل H الإمكانيات المعمارية؟

دور الفولاذ على شكل H في تصاميم المباني المعقدة

يختار البناء الفولاذ على شكل H لأنه يعمل بشكل جيد في التصاميم الراقية والتخطيطات المفتوحة. يمكن أن تغطي مساحات واسعة دون دعم إضافي ، مما يجعل مناطق كبيرة لأماكن مثل المطارات أو الملاعب أو المحلات التجارية. كما تجعل أحجامها العادية من السهل تطابقها مع أجزاء البناء الأخرى.

تكييف H شكل الصلب لمتطلبات هيكلية متنوعة

تأتي شعاع H في جميع أنواع الأحجام والسمك ، وتتناسب مع كل شيء من الإطارات الخفيفة إلى الإعدادات الصناعية الثقيلة. يمكنهم الوقوف على ارتفاع كأعمدة أو الاستلقاء مسطحة كأعمدة، اعتمادا على الخطة. كما أنها تزوج بشكل جيد مع أشياء مثل لوحات الخرسانة أو الخرسانات.

خيارات التخصيص المتاحة مع H شكل الصلب الملفات الشخصية

يحتوي ورشة الصلب على 25 خط تشكيل و 15 خط ثقب ، مما يجعل الكثير من منتجات الصلب ، بما في ذلك حزم H مخصصة لوظائف محددة. وتلتزم ورشة العمل بنظام إدارة 6S، مما يضمن عمل عالي الجودة يلبي المعايير المحلية والعالمية.

لماذا هي المتانة وطول العمر ميزة رئيسية لهياكل الصلب على شكل H؟

مقاومة الضغوط البيئية في إطارات الصلب على شكل H

الفولاذ على شكل H يحافظ بشكل طبيعي على الآفات والعفن والتعفن والأضرار الشمسية - الأشياء التي تدمر الهياكل الخشبية. مع الطلاءات أو الجلفنة ، فإنه يحارب أيضًا الصدأ من البقع الرطبة أو الكيميائية الثقيلة.

سلامة هيكلية طويلة الأجل للمباني باستخدام H شكل الصلب

على عكس الخشب أو الخرسانة ، والتي يمكن أن تلوي أو تضعف مع مرور الوقت ، يبقى الفولاذ على شكل H صلبا تحت الوزن لسنوات. هذا يعني أنك لا’ تحتاج إلى التحقق منها أو إصلاحها في كثير من الأحيان.

اعتبارات الصيانة للاستخدام الطويل

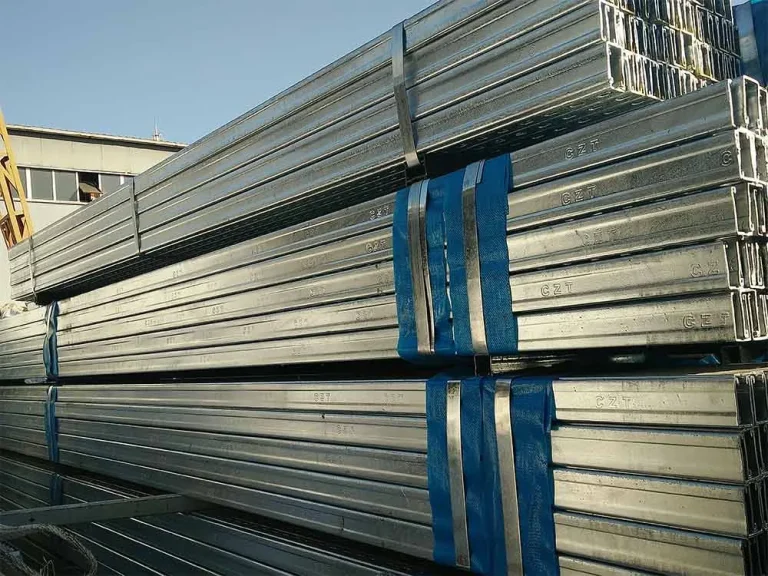

نحن نستخدم فولاذ Q235B و Q345B HDG - هذه الأنواع التي تستخدمها CZT تتحمل بشكل جيد التآكل والطقس. المعالجة السطحية، سواء كانت مغلفنة بالغمر الساخن، أو مغلفنة مسبقا، أو طلاء مخصص، تساعد على خفض متطلبات الصيانة وتقليل تكاليف الصيانة الهيكلية على المدى الطويل.

ما هي الطرق التي يحسن بها H Shape Steel السرعة والكفاءة في البناء؟

تبسيط عملية البناء باستخدام شعاع H مسبقًا

التصنيع المسبق يعني أن شعاع H يتم صنعه خارج الموقع في أماكن خاضعة للسيطرة. ورشة العمل لديها 2 آلات القطع بالليزر و 3 آلات الانحناء ، مما يتيح لهم جلد الأعمدة بسرعة ، حتى لأوامر خاصة.

تقليل العمالة في الموقع من خلال التجميع المبسط

مع الأشكال المنتظمة والأحجام الدقيقة، لا’ t تحتاج الكثير من تعديل في الموقع. وهذا يوفر وقت العمل ويجعل البناء أكثر أماناً عن طريق تقليل المهام العالية.

الجداول الزمنية للمشروع وفوائد الجدولة الزمنية لاستخدام H Shape Steel

البناء الأسرع يعني أن المشاريع تنتهي بسرعة أكبر، وهو أمر مهم جدا عندما يكون الوقت المال. الموردين مثل CZT يقدمون في الوقت المحدد عبر المناطق ، مما يساعد على الحفاظ على الخطط على المسار الصحيح.

كيف تؤثر فعالية التكلفة لاستخدام H Shape Steel على ميزانيات المشروع؟

انخفاض تكاليف دورة الحياة بسبب انخفاض احتياجات الصيانة

الصلب’ صلابة S تعني إصلاحات أقل مقارنة بالخشب أو الخرسانة ، والتي يمكن أن تتصدع أو تتعفن. وهذا يجعل الفولاذ على شكل H اختيار ذكي لتوفير النقود مع مرور الوقت.

توفير المواد من خلال توزيع الوزن الأمثل

بفضل نسبة القوة إلى الوزن العالية ، يستخدم الفولاذ على شكل H مواد أقل لإنجاز العمل ، مما يوفر تكاليف المواد. كما خفضت الحمولات الخفيفة نفقات الشحن.

مزايا تخطيط الميزانية مع الأداء المتوقع

يمكن للمهندسين معرفة الصلب على شكل H ’ قدرة التحميل مع الرياضيات البسيطة. هذا يقلل من التخمين في التخطيط ويقلل التكاليف الإضافية للمفاجآت.

لماذا الاستدامة سبب متزايد لاختيار H Shape Steel؟

قابلية إعادة التدوير والتأثير البيئي للفولاذ الهيكلي H Beams

الصلب هو واحد من المواد الأكثر إعادة تدوير حول. معظم الصلب الهيكلي يحتوي على محتوى إعادة تدويره ويمكن إعادة استخدامه دون فقدان القوة بعد سقوط المبنى.

كفاءة الطاقة في إنتاج واستخدام H Shape Steel

الطرق الجديدة لجعل الصلب يستخدم طاقة أقل لكل طن من الطرق القديمة. كما توفر الهياكل الخفيفة الطاقة أثناء الشحن والبناء.

تلبية معايير البناء الأخضر بالمواد المستدامة

استخدام الصلب القابل لإعادة التدوير يساعد المشاريع على تلبية المعايير الخضراء مثل LEED. هذا أمر كبير لكل من المباني العامة والخاصة في هذه الأيام.

ما هي خصائص مقاومة الحريق من فولاذ هيكلي H شعاع؟

قدرات تصنيف الحريق لمكونات الصلب الهيكلي المعالجة

مع الطلاء الآمن من الحريق أو الطلاءات مثل الطبقات المتداخلة ، يمكن للفولاذ على شكل H أن يلبي قواعد الحريق الصارمة ، والتي غالباً ما تستمر أكثر من ساعتين ، اعتماداً على الطلاء.

تعزيز سلامة المباني مع عناصر التصميم المقاومة للحريق

على عكس الخشب ، الذي يحترق بسرعة ، أو الخرسانة ، التي يمكن أن تتصدع في الحرارة ، فإن الفولاذ المعالج على شكل H يستمر لفترة أطول في الحرائق. وهذا يعطي الناس المزيد من الوقت للخروج ومطفي الإطفاء المزيد من الوقت للتصرف.

كيف يمكن مقارنة فولاذ هيكلي H شعاع مع مواد الإطار البديلة؟

اختلافات الأداء بين الخرسانة والخشب والصلب على شكل H

الخرسانة قوية للدفع ولكن ضعيفة للسحب دون مساعدة إضافية. الخشب ينحني ولكن يحترق بسهولة. فولاذ على شكل H يوازن كل من ويعمل بشكل جيد لجميع أنواع الوظائف.

تقييم الملاءمة عبر أنواع المباني المختلفة

من مباني المكاتب الطويلة التي تحتاج إلى فترات طويلة إلى منازل Carports تحتاج إلى مقاومة الصدأ-CZT نوع A / B / C Carport يستخدم Q235B ، و Q355B فولاذ الكربون-H حزم تناسب الكثير من الاستخدامات لأنها ’ re مرنة جدا.

ما الذي يجب أن نأخذ في الاعتبار عند تحديد فولاذ هيكلي H شعاع؟

الأبعاد القياسية والدرجات لاستخدام البناء

الأحجام القياسية تجعل شعاع H يعمل مع موردين مختلفين. تحدد الدرجات مثل Q235B / Q355B مستويات القوة للتصاميم الآمنة بناءً على الظروف المحلية ، مثل الزلازل أو الثلج.

العوامل الهندسية التي تؤثر على اختيار الشعاع

طول المدى ، ونوع الحمل (نقطة أو انتشار) ، وطرق الاتصال (ملبوسة أو ملحومة) ، وحدود الانحراف من جميع خيارات شعاع التوجيه ، جنبًا إلى جنب مع احتياجات التصميم مثل ارتفاع السقف أو المسافة بين الأعمدة.

أين يمكنك رؤية التطبيقات المتنوعة لـ H Beams في العمل؟

الاستخدامات التجارية والصناعية والسكنية للفولاذ الهيكلي

تستخدم شعاع H في كل شيء من رف المستودعات إلى دعم الجسر. CZT تقدم OEM و توفر عينة للمنتجات مثل قطع غيار القطع بالليزر OEM & أجزاء اللحاممصنوعة لهذه الاستخدامات.

أمثلة على المباني عالية الأداء التي تستخدم إطارات شكل H

تظهر أنظمة تركيب الشمسية H على شكل فولاذ ’ قوة S. إن نظام تتبع محور واحد CZT يحمل الألواح الشمسية المتحركة على محور واحد، بنيت مع أطر شعاع H قوية التي تتعامل مع أحمال الثلج / الرياح تصل إلى 216km / h و 1.4kn / م2.

من هو CZT وماذا نقدم في مجال الصلب الهيكلي؟

التزامنا بالجودة في تصنيع فولاذ هيكلي H Beams

معايير التصنيع الدقيق في CZT

تتبع ورشة العمل نظام إدارة 6S ، والحفاظ على العمل بسلاسة ودقة.

شهادات المواد والامتثال

شهادة: تظهر ISO و SGS أن منتجاتنا تلبي المعايير العالمية.

مجموعة المخزون: الأحجام والدرجات والأوامر المخصصة

نحن نقدم OEM & عينة: الخدمات المتاحة عبر مخزوننا.

معالجات السطح وخيارات الحماية من التآكل

تشمل الخيارات HDG (المغلفنة بالغمس الساخن) ، المغلفنة مسبقا ، أو العلاجات المخصصة بناء على ما تحتاجه الوظيفة.

دعم لوجستي للتسليم على نطاق واسع

CZT’ يقدم فريق الخدمة الدولي حلول مصممة خصيصا للعملاء العالميين ، وضمان التسليم في الوقت المناسب.

أسئلة متكررة

س: لماذا اختيار فولاذ على شكل H على I-beams؟

ج: الفولاذ على شكل H لديه شفات أوسع لنشر الحمل بشكل أفضل ، وخاصة تحت الانحناء ، مما يجعله أكثر فائدة للكثير من الوظائف.

س: هل يمكن استخدام الفولاذ على شكل H في الخارج دون الصدأ؟

ج: نعم. مع العلاجات مثل الجلفنة بالغمر الساخن (HDG) ، فإنه يحارب الصدأ بشكل جيد ، حتى في الأماكن الخارجية الصعبة مثل بالقرب من البحر.

س: كيف يمكنني اختيار حجم شعاع H الصحيح؟

ج: الحجم يعتمد على طول المدى ونوع الحمل وحدود الانحراف. تحدث مع مهندس أثناء التخطيط لاختيار المهندس المناسب.

س: هل الأشعة H جيدة للمناطق المعرضة للزلازل؟

ج: نعم. تساعد مرونتها على امتصاص الطاقة أثناء الزلازل ، مما يقلل من مخاطر الانهيار مقارنة بالمواد الصلبة.

س: هل يمكن إعادة تدوير الفولاذ على شكل H بعد هدم المبنى؟

ج: نعم. يحافظ الصلب على قوته من خلال العديد من دورات إعادة التدوير ، مما يجعله مادة خضراء جدا.