What Makes the High Strength-to-Weight Ratio of H Shape Steel So Valuable?

How H Shape Steel Optimizes Load-Bearing Performance

H shaped steel, also known as H-beam or wide flange beam, has a special shape that makes it great for holding up heavy stuff. Its flat sides and upright middle part help it fight bending and twisting. This setup puts material where it’s needed most, keeping the beam light but strong. So, H shaped steel can carry big loads over long stretches without bending or snapping.

Why Structural Efficiency Matters in Modern Construction

In today’s building work, efficiency means doing a lot with a little. H shaped steel’s high strength-to-weight ratio lets builders use lighter frames that stay tough. This takes pressure off foundations, makes shipping easier, and speeds up the job. For tall buildings, bridges, or factories, this means more open space and less wasted stuff.

Comparing Strength Metrics of H Shape Steel to Other Structural Materials

Compared to wood or concrete, H shaped steel is way stronger for both pulling and pushing forces. Wood is fine for small jobs but isn’t as steady or fire-safe as steel. Concrete handles pushing well but needs extra help for pulling. H shaped steel does both in one piece, making it perfect for rough conditions like wind or quakes.

How Does the Design Flexibility of H Shape Steel Enhance Architectural Possibilities?

The Role of H Shape Steel in Complex Building Designs

Builders pick H shaped steel because it works well in fancy designs and open layouts. It can cover wide spaces without extra support, making big areas for places like airports, stadiums, or shops. Its regular sizes also make it simple to match with other building parts.

Adapting H Shape Steel to Diverse Structural Requirements

H beams come in all kinds of sizes and thicknesses, fitting everything from light frames to heavy industrial setups. They can stand tall as posts or lie flat as beams, depending on the plan. They also pair nicely with things like concrete slabs or trusses.

Customization Options Available with H Shape Steel Profiles

The steel workshop has 25 forming lines and 15 punching lines, making lots of steel products, including custom H beams for specific jobs. The workshop sticks to the 6S management system, ensuring top-quality work that meets local and world standards.

Why Is Durability and Longevity a Key Advantage of H Shape Steel Structures?

Resistance to Environmental Stressors in H Shape Steel Frameworks

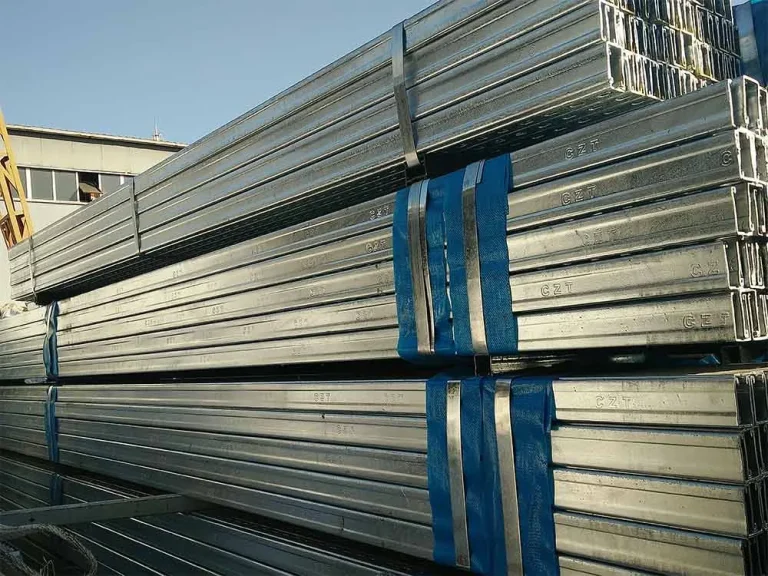

H shaped steel naturally keeps out pests, mold, rot, and sun damage—things that wreck wood structures. With coatings or galvanization, it also fights rust from wet or chemical-heavy spots.

Long-Term Structural Integrity of Buildings Using H Shape Steel

Unlike wood or concrete, which can twist or weaken over time, H shaped steel stays solid under weight for years. This means you don’t need to check or fix it as often.

Maintenance Considerations for Prolonged Use

We use Q235B and Q345B HDG steel—these types used by CZT hold up well against wear and weather. The surface treatment, whether it is hot-dip galvanized, pre-galvanized, or a custom coating, helps lower maintenance requirements and reduces long-term structural upkeep costs.

In What Ways Does H Shape Steel Improve Speed and Efficiency in Construction?

Streamlining the Construction Process with Prefabricated H Beams

Prefabrication means H beams are made off-site in controlled places. The workshop has 2 laser cutting machines and 3 bending machines, letting them whip up beams fast, even for special orders.

Reducing On-Site Labor Through Simplified Assembly

With their regular shapes and exact sizes, prefabricated H beams don’t need much tweaking on-site. This saves work time and makes building safer by cutting down on high-up tasks.

Project Timelines and Scheduling Benefits of Using H Shape Steel

Quicker building means projects finish faster, which matters a lot when time is money. Suppliers like CZT deliver on time across regions, helping keep plans on track.

How Does the Cost-Effectiveness of Using H Shape Steel Impact Project Budgets?

Lower Lifecycle Costs Due to Reduced Maintenance Needs

Steel’s toughness means fewer fixes compared to wood or concrete, which can crack or rot. This makes H shaped steel a smart pick for saving cash over time.

Material Savings Through Optimal Weight Distribution

Thanks to its high strength-to-weight ratio, H shaped steel uses less material to get the job done, saving on material costs. Lighter loads also cut shipping expenses.

Budget Planning Advantages with Predictable Performance

Engineers can figure out H shaped steel’s load capacity with simple math. This cuts out guesswork in planning and lowers extra costs for surprises.

Why Is Sustainability a Growing Reason for Choosing H Shape Steel?

Recyclability and Environmental Impact of Structural Steel H Beams

Steel is one of the most recycled materials around. Most structural steel has recycled content and can be reused without losing strength after a building comes down.

Energy Efficiency in Production and Use of H Shape Steel

New ways of making steel use less energy per ton than older methods. Lighter structures also save energy during shipping and building.

Meeting Green Building Standards with Sustainable Materials

Using recyclable steel helps projects meet green standards like LEED. This is a big deal for both public and private buildings these days.

What Are the Fire Resistance Properties of Structural Steel H Beams?

Fire Rating Capabilities of Treated Structural Steel Components

With fire-safe paint or coatings like intumescent layers, H shaped steel can meet tough fire rules, often lasting over two hours, depending on the coating.

Enhancing Building Safety with Fire-Resistant Design Elements

Unlike wood, which burns fast, or concrete, which can crack in heat, treated H shaped steel holds up longer in fires. This gives folks more time to get out and firefighters more time to act.

How Does Structural Steel H Beam Compare to Alternative Framework Materials?

Performance Differences Between Concrete, Wood, and H Shape Steel

Concrete is strong for pushing but weak for pulling without extra help. Wood bends but burns easily. H shaped steel balances both and works well for all kinds of jobs.

Evaluating Suitability Across Different Building Types

From tall office buildings needing long spans to home carports needing rust resistance—CZT Type A/B/C Carport uses Q235B, and Q355B carbon steel—H beams fit lots of uses because they’re so flexible.

What Should Be Considered When Specifying Structural Steel H Beams?

Standard Dimensions and Grades for Construction Use

Standard sizes make H beams work with different suppliers. Grades like Q235B/Q355B set strength levels for safe designs based on local conditions, like quakes or snow.

Engineering Factors That Influence Beam Selection

Span length, load type (point or spread), connection methods (bolted or welded), and deflection limits all guide beam choices, along with design needs like ceiling height or column spacing.

Where Can You See the Versatile Applications of H Beams in Action?

Commercial, Industrial, and Residential Uses of Structural Steel Beams

H beams are used in everything from warehouse racks to bridge supports. CZT offers OEM & sample availability for products like OEM Laser Cutting Parts & Welding Parts, made for these uses.

Examples of High-Performance Buildings Utilizing H Shape Frameworks

Solar mounting systems show H shaped steel’s strength. The CZT One Axis Tracking System holds solar panels moving on a single axis, built with tough H beam frameworks that handle snow/wind loads up to 216km/h and 1.4kn/m².

Who Is CZT and What Do We Offer in the Field of Structural Steel?

Our Commitment to Quality in Manufacturing Structural Steel H Beams

Precision Fabrication Standards at CZT

The workshop follows the 6S management system, keeping work smooth and accurate.

Material Certifications and Compliance

Certification: ISO and SGS show our products meet world standards.

Inventory Range: Sizes, Grades, and Custom Orders

We offer OEM & Sample: Available services across our stock.

Surface Treatments and Corrosion Protection Options

Options include HDG (Hot-Dip Galvanized), pre-galvanized, or custom treatments based on what the job needs.

Logistics Support for Large-Scale Delivery

CZT’s international service team gives tailored solutions for global customers, ensuring on-time delivery.

FAQ

Q: Why pick H shaped steel over I-beams?

A: H shaped steel has wider flanges for better load spreading, especially under bending, making it more useful for lots of jobs.

Q: Can H shaped steel be used outside without rusting?

A: Yes. With treatments like hot-dip galvanization (HDG), it fights rust well, even in tough outdoor spots like near the sea.

Q: How do I choose the right H beam size?

A: Size depends on span length, load type, and deflection limits. Talk to an engineer during planning to pick the right one.

Q: Are H beams good for earthquake-prone areas?

A: Yes. Their flexibility helps absorb energy during quakes, lowering collapse risks compared to stiff materials.

Q: Can H shaped steel be recycled after a building is torn down?

A: Yes. Steel keeps its strength through lots of recycling cycles, making it a very green material.