What Makes Shaped Steel a Key Component in Industrial Efficiency?

The Unique Properties of Shaped Steel

Shaped steel, formed into shapes like beams, channels, or angles, is treasured for its strength and versatility. It stands firm under heavy weights, resisting twists or cracks. Its tough nature makes it vital for demanding factory jobs. For example, H Steel Beams are built to carry big loads for specific tasks. Shaped steel also molds easily into forms like Z Steel Channels or Omega Steel Beams. This adaptability fits a wide range of building and machine needs, making it a favorite for plants and work sites.

On top of that, shaped steel fights wear well. It holds up in harsh weather, from blazing sun to icy cold. This strength saves on repairs, cutting costs and time. Its precise shaping suits many projects, from tall structures to heavy equipment, ensuring steady performance.

How Shaped Steel Enhances Durability and Performance

Shaped steel’s solid build adds years to buildings and machines. It resists tough conditions without rusting or breaking. For instance, the Unistrut channel is crafted to last while being easy to set up on job sites. Its steady quality delivers even results across tasks. This reduces fixes and keeps work running smoothly.

Moreover, shaped steel’s toughness cuts the risk of failure. In big machines, it holds parts under strain, ensuring safe and reliable operation. Its ability to withstand damage suits outdoor projects, where weather can be rough, keeping systems strong and dependable.

How Does Shaped Steel Optimize Manufacturing Processes?

The Role of Shaped Steel in Reducing Production Time

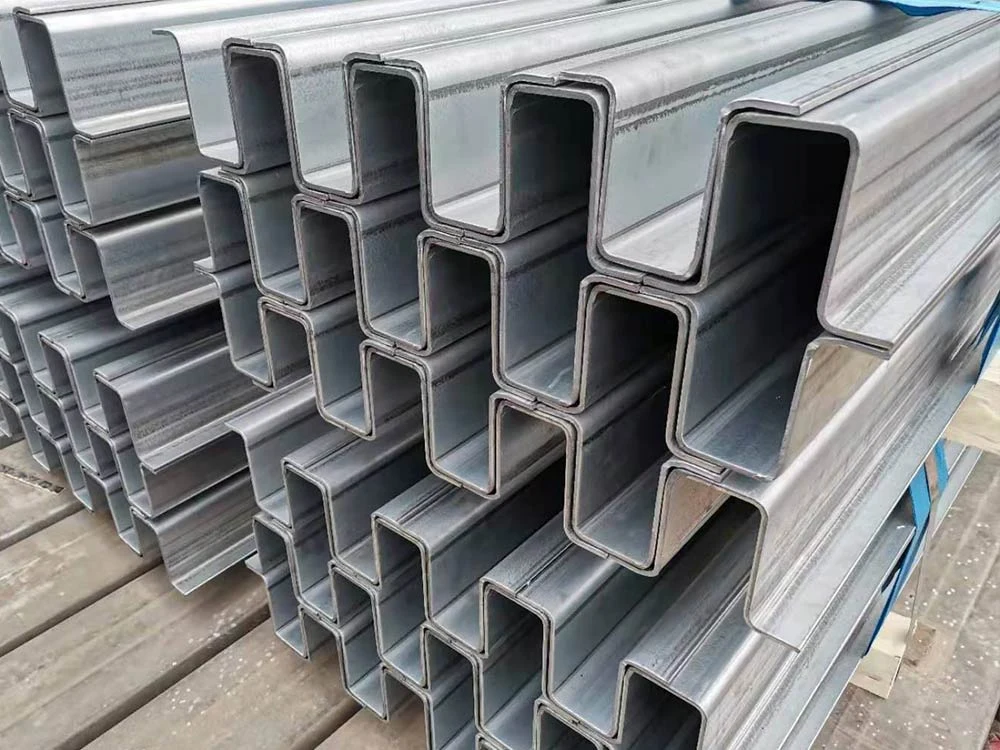

Shaped steel parts come pre-shaped to exact measures. This skips major changes during assembly. Ready pieces save hours and lower worker costs. For example, C Steel Channels are made for specific roles. They fit right into factory lines, speeding up tasks. Using steel crafted to tight rules helps plants work faster and better. It also cuts mistakes during setup, boosting total output.

Pre-shaped steel arrives ready to use. This means less cutting or fitting on-site. Factories can push from start to finish quickly, meeting strict deadlines with ease.

Cost Efficiency Achieved Through the Use of Shaped Steel

Shaped steel saves money due to its long life and low repair needs. Its sturdiness means fewer replacements over time. This lowers expenses for industries using big machines or large structures. Plus, steel can be recycled, backing green habits and trimming material costs. Products like Z Steel Channels blend strength with savings on big jobs.

Using shaped steel also reduces waste. Its precise fit leaves less scrap during building or production. This keeps projects within budget while delivering great results.

Why Is Shaped Steel Essential Across Various Industries?

Applications of Shaped Steel in Heavy Machinery

In crafting heavy machines, shaped steel shines for its power and exact fit. Parts like Omega Steel Beams give equipment the support needed for lifting heavy loads, like in cranes or loaders. These beams can be tailored to meet specific needs, ensuring top work in tough settings.

Shaped steel’s strength suits machines that run non-stop. Its accuracy ensures parts join perfectly, reducing breakdowns and lengthening machine life.

The Impact of Shaped Steel on Construction and Infrastructure

Shaped steel is a cornerstone of modern building work. Its strength-to-weight balance makes it perfect for frames, bridges, and major projects. For instance, H Steel Beams are used for their power to hold heavy loads and install fast. They speed up construction while keeping structures safe against wind or shakes.

In infrastructure, shaped steel offers lasting support. It backs projects like roads or rail lines, where safety is key. Pre-shaped parts also cut building time, keeping projects on track.

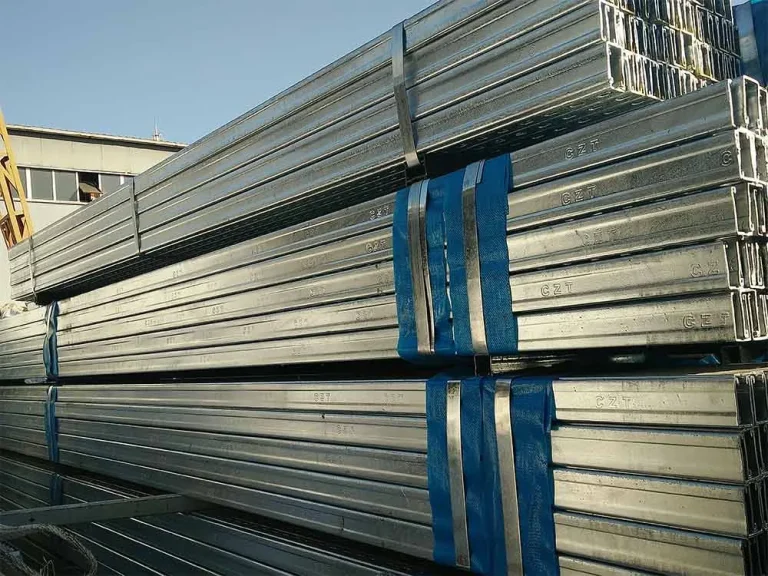

What Sets CZT’s Shaped Steel Apart?

Who We Are at CZT

CZT is a top name in crafting high-quality shaped steel. As of June 24, 2025, we focus on new ideas and careful work, earning trust across fields. Our products serve areas like construction, factories, and heavy equipment. We offer a broad range of shaped steel, including channels, beams, and custom forms, all made for specific tasks.

Our aim is to deliver top steel that meets tough standards. This drive makes us a dependable partner for firms needing strong materials for their projects.

Our Commitment to High-Quality Shaped Steel Production

Precision Engineering in Our Shaped Steel Products

At CZT, we prioritize exact design. Our shaped steel parts are carefully made to precise sizes. This ensures they work well and stay solid. For example, H Steel Beams are crafted for heavy jobs, like supporting bridges or large buildings. These beams carry big loads and keep structures steady, perfect for tough tasks.

Likewise, C Steel Channels are pre-made for specific uses. Their exact sizes make setup quick, saving time and worker costs. Using modern tools, we ensure every piece meets high marks for fit and strength. This care helps clients finish jobs fast without losing quality.

Superior Material Selection for Enhanced Performance

Our shaped steel starts with the best raw materials. At CZT, we choose top-grade steel to boost lifespan and workability. This ensures our products resist rust, wear, and harsh weather. For instance, Unistrut channels are built to last while being simple to assemble. They’re a top choice for building jobs needing firm support.

Our Omega Steel Beams also stand out. They mix power with adaptable shapes, ideal for machines under constant stress. By blending great materials with smart design, we deliver steel that goes beyond industry hopes, giving clients steady results every time.

How CZT’s Shaped Steel Drives Industrial Progress

Shaped steel is key to speeding up industry work and supporting greenways. Its flexibility fits many fields, driving growth through better performance and lower costs.

For instance, Z Steel Channels are made for strength and savings in large jobs. They suit tasks from building frames to machine parts. By offering pre-shaped parts that fit right into workflows, CZT’s steel helps plants cut pauses and use resources well.

In construction, our steel solutions make projects quicker and safer. The strength-to-weight balance of H Steel Beams holds up against forces like wind or quakes. This mix of speed and safety shows why shaped steel is vital for modern buildings.

Extra Benefits of CZT’s Shaped Steel

Our shaped steel also improves safety. Its solid strength stops failures in key systems, like machine bases or building supports. This lowers risks for workers and tools. Plus, our steel’s even quality ensures sure results, helping planners avoid costly errors.

We offer custom shapes, too. Clients can request unique forms, like tailored Z Steel Channels for special jobs. This adaptability ensures our steel fits any task, from small setups to huge projects.

Shaping the Future with CZT’s Shaped Steel

CZT’s steel supports green goals. Its recyclability cuts waste and saves resources. Our lasting designs mean fewer swaps, lowering costs over time. This balance of efficiency, strength, and eco-friendly benefits drives the industry forward.

Looking ahead, shaped steel will remain key as industries grow. Its ability to meet new needs, like taller structures or smarter machines, keeps it central. CZT’s focus on quality and fresh ideas prepares us to meet these future demands.

Real-World Cases of CZT’s Shaped Steel

Consider a bridge project. H Steel Beams from CZT form the core, supporting heavy traffic while resisting storms. Their pre-cut sizes speed setup hummed-up assembly, letting crews finish early. In factories, Omega Steel Beams hold up big cranes, ensuring smooth work in tough conditions.

In energy projects, like wind turbines, C Steel Channels provide light yet strong frames. Their durability reduces upkeep costs, saving money over time. These examples show how CZT’s steel boosts efficiency and trust across fields.

FAQ

Q: What are the main benefits of using shaped steel in industrial applications?

A: Shaped steel offers great strength, lasts in tough settings, and fits many shapes. Pre-cut parts save time and worker costs.

Q: How does shape steel contribute to environmental sustainability?

A: Steel can be reused, reducing waste and saving materials. Its long life cuts the need for new parts, aiding green practices.

Q: Can shaped steel be customized for specific project requirements?

A: Yes, it can be molded into shapes like channels or beams to match the exact needs of buildings or factories.

Q: Why is prefabrication important when using shaped steel?

A: Pre-shaped parts are ready to use, cutting on-site work and speeding up project timelines.

Q: Which industries benefit most from CZT’s shaped steel products?

A: Construction, heavy equipment, automotive, and energy fields rely on CZT’s steel for its versatility and strength.